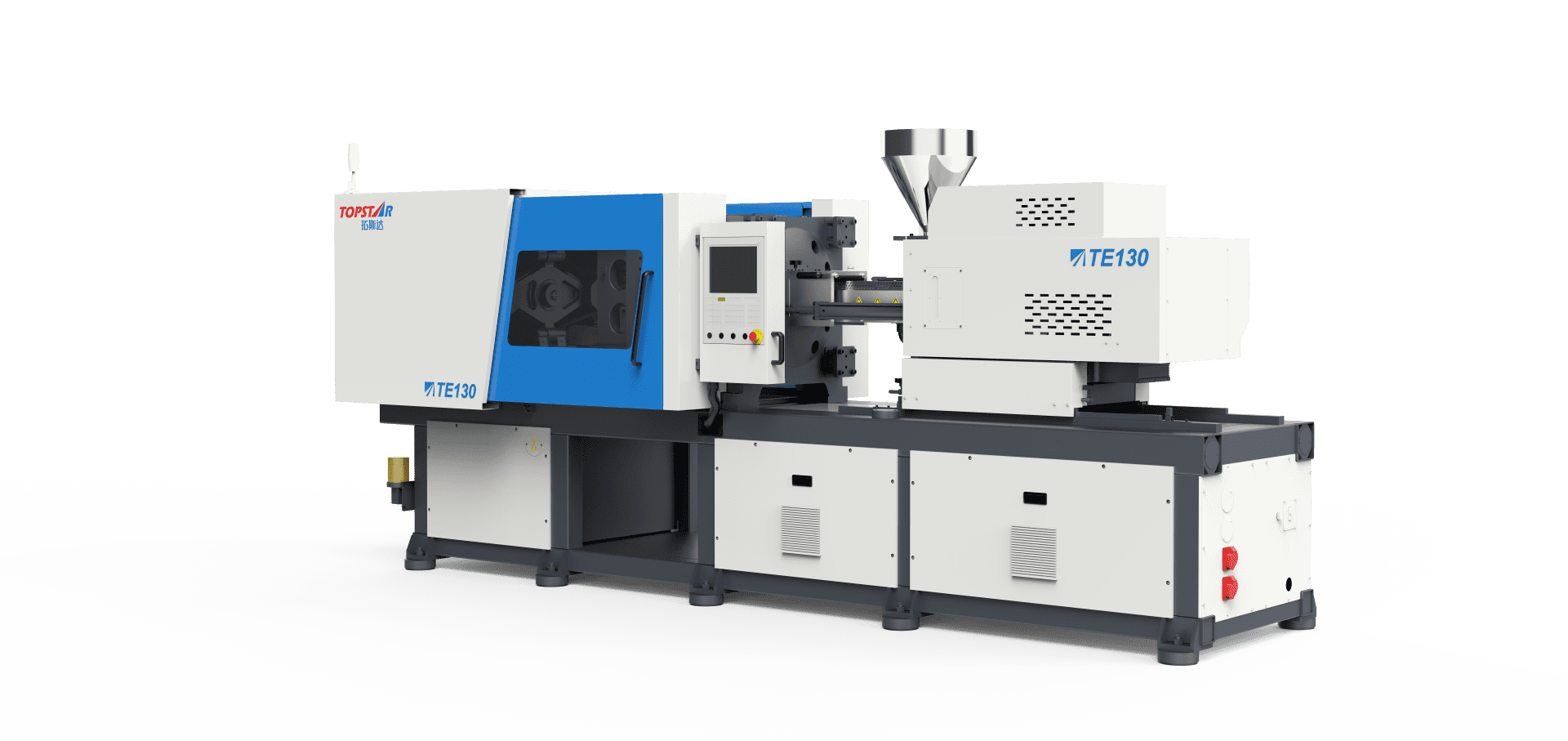

A plastic-molding machine is a good choice for many plastic manufacturing companies, and it can often be seen in their workshops. They create both custom and mass-produced products, which means they have great potential to save time and money compared to other types of machines. Here today, we will share why your business needs such a machine.

The purpose of a plastic-molding machine is to change the shape of plastic to create a new product!

Plastic-molding machines serve many different purposes, but the main goal is always to change the shape of plastic to create new products. It does this by heating the plastic and then pressing it into a mold created especially for this purpose. This process may take several hours.

The result is similar to what you’d expect from any other type of manufacturing process: the finished edge is clean, and the watch is free of any flaws or cracks. In addition to keeping your customers happy, it will look good enough both aesthetically and functionally, and it will help reduce waste!

Having a plastic-molding machine can also help with production costs!

Having a plastic molding machine also helps in reducing production costs. It can do the work of several people, which means you don’t need to hire as many employees. This can also save on labor costs if you manufacture products in high volumes and need to produce them quickly. Finally, with the many different types of plastic molding machines available today, it is now easier than ever for your business to use them!

You can get a lot more done with a plastic-molding machine than with a standard injection molding machine!

You can get a lot more done with a plastic-molding machine than with a standard injection molding machine. For example, you can use it to produce larger or smaller parts. You can also produce parts with different geometries than you could with an injection molding machine. You may need to create a set of parts with different properties. For example, if a part is lightweight, a part needs strength and durability.

The biggest advantage of this type of equipment is its versatility. It gives businesses the freedom they need while maintaining quality control standards to keep your customers happy and coming back again!

They help your business meet the needs of mass production and customization at the same time!

If you run a business and are looking for a way to increase your production capacity, then a plastic-molding machine is exactly what you need. These machines mass-produce items quickly and efficiently while still maintaining quality. They are ideal for producing a large number of products simultaneously and allow for customization.

Since these machines can produce many different types of products, they are ideal for businesses that need a diverse inventory. Also, since plastic molding equipment is relatively inexpensive, most companies choose to purchase them. This gives them access when they need it without the huge upfront cost of buying new tools.

Plastic-Molding Machines Provide a High-Performance Machine with a Simple Design!

You might be wondering why your business needs a plastic-molding machine. To put it simply, these machines provide a high-performance machine with a simple design that makes them easy to understand and operate.

This is important because when you run a business you want to spend your time on the important things. You don’t want to spend hours understanding how things work. You want it done immediately so you can get back to what matters most. The last thing any entrepreneur wants is an expensive piece of idle equipment that takes up space and wastes money.

To sum up

Plastic molding is a great way to expand your business, and we share this to make it easier for business owners to understand why they are so popular. We can see too many plastic products in our lives, and such a machine has gradually been derived. If you are interested in other types of injection molding machines, welcome to the official website of Topstar!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC