How to Choose A Best Robot Arm in 2022?

2022/04/28 By 兰兹

The plastic mold design process

A robot arm is a mechanical arm, usually programmable, with similar functions to a human component. The hand can be either an independent mechanism or part of a more complex robot.

The manipulator segments have connections that allow rotational or translational movements. The robotic arm ends with a gripping mechanism or a working tool.

Classification of robotic arms

According to the fundamental structure

TOPSTAR manipulators are the simplest of all stationary robots. Typical Cartesian robots have three linear freedom axes perpendicular to each other, providing a rectangular box-shaped workspace.

Moreover, due to robot arm relative simplicity, compared to other types of robots, Cartesian robots are less expensive than their counterparts. Because of their rigid construction, this type of robot has good accuracy and repeatability. For example, the KUKA RL16 3-axis Cartesian robot has a repeatability of +/- 0.1 mm.

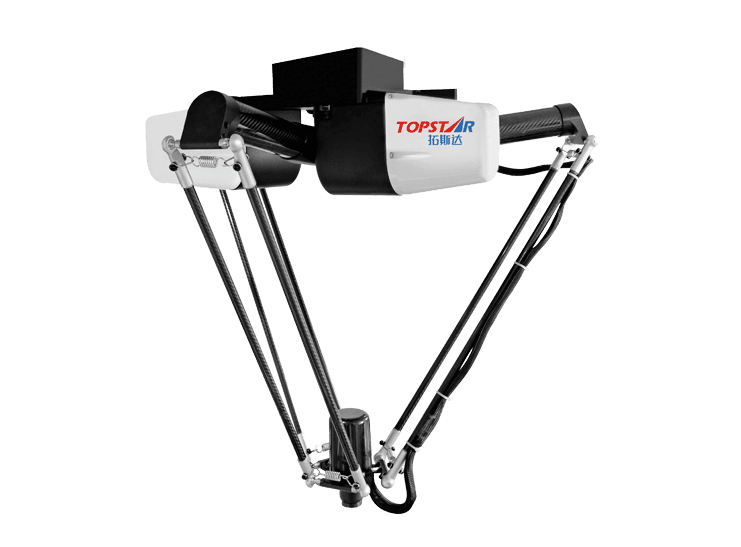

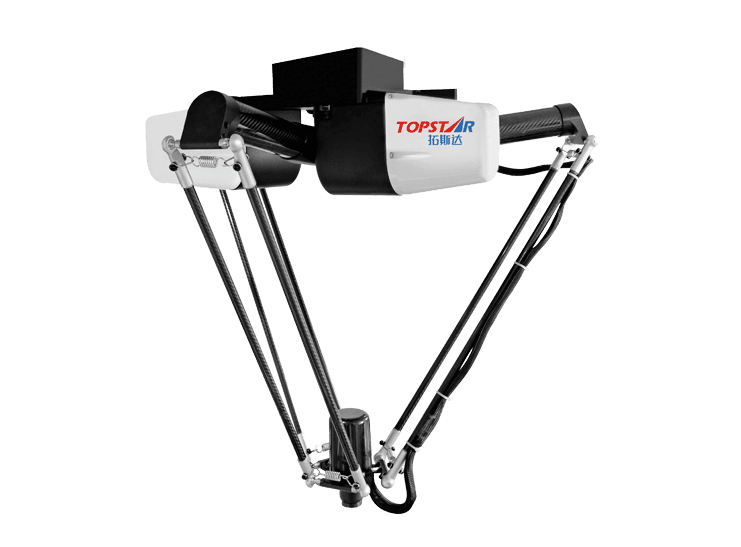

TOPSTAR manipulators usually have several arms connected in parallel, mainly cylindrical, which provides positioning in one selected plane. Moreover, due to the possible deformation at the total reach of the lever, as a rule, they do not have a high load capacity, but the robot arm can boast good speed and accuracy. Traditionally used in assembly lines.

By type of management:

- Unmanaged;

- Moreover, Command;

- Furthermore, Hard-coded;

- Adaptive.

Sponge type:

- Hard;

- Similarly, Adjustable;

- Flexible;

- In addition, Springy.

Drive type:

- Spring;

- Pneumatic;

- Hydraulic;

- Electromechanical.

How to choose a robotic arm?

When choosing robotics, you need to understand exactly what tasks the robot will perform. Moreover, this is the main criterion when selecting the type, size, and capabilities of the robot you want to buy. Depending on this, other measures can be determined.

The payload is the maximum load the robot can move in the workspace. If you want to transfer a part from one machine to another, you need to include the region’s weight and the importance of the robot arm gripper in the payload.

Articulated robotic arms have swivel joints.

Articulated robotic arms have swivel joints ranging from two to 10 or more. Moreover, manipulators of this type are mounted on a rotating base. Swivel joints connect the segments of the arm. Each connection is called an axis and provides an additional degree of freedom. Industrial robots usually have four or six axes.

- Step 1: Receive products from customers.

- Step 2: Identify the plastic material. You will need to consult and coordinate with the customer to choose this suitable plastic material at this step. Moreover, at the same time, this determination is also a premise for you to choose the right robot arm.

- 3: Select mold material. Usually, the mold material will be steel alloy because steel has excellent bearing capacity and heat resistance.

- Step 4: Determine the size and details of the kit.

- Step 5: Conduct plastic mold design on specialized software: CAE, CAM, Catia, etc. You will need to clearly show each size and small details on the plastic mold design. Because it will make it easier for technicians to process and assemble molds.

Plastic injection mold design process

The design process of plastic injection mold is quite similar to that of plastic injection mold. Moreover, it also includes the same five steps as above. You can use the robot arm to use for plastic injection molds.

Plastic mold design software

Currently, there are many plastic mold design software that you can use. Most software has advanced features that help to cast engineers’ design molds more easily. Some commonly used mold design software:

- CAE

- AutoCAD

- Catia

- ORANGE

Plastic injection mold design guide

Moreover, to complete a plastic injection mold design, engineers will need to go through 5 different stages.

Stage 1: Mold manufacturing process

- 1: Identify the product

- 2: Determine mold yield

- 3: Determine the product layout

- 4: Determine the size of the mold cover

- Step 5: Determine the robot arm

Stage 2: Mold design process

3 Stage: Product design process

Stage 4: Design process of the channel system

Stage 5: Design process of cooling system

What elements does a mold design engineer need?

Moreover, to become a professional mold design engineer, you will need to prepare the following elements fully:

- Graduated from university or college majoring in mechanical engineering

- Having professional knowledge about molds in the plastic industry

- Ability to use modern machine tools such as CNC machines.

- Good use of design software: AutoCAD, Catia, CAE.

- Able to read and understand documents in English

In addition, a robot arm needs to have other soft skills and a sense of responsibility at work. Specifically, they need to understand and design molds based on customer needs. Moreover, hard work and enthusiasm at work areare the premise for future engineers’ development.

Moreover, collaborative robotic arms are a kind of articulated robot with intelligent control technology and high-precision sensors to facilitate human interaction and improve safety. These can be quickly installed anywhere and for any purpose that suits your production needs.

The robot arm is conditionally divided by the payload

Robotic arms are conditionally divided by cargo by the weight of objects they can manipulate. In many applications, compact dimensions are more important than load capacity, so manufacturers offer a wide selection according to this criterion:

Moreover, robotic arms are divided according to the field of application because. In addition to universal robotic hands, there are highly specialized ones adapted to specific manipulations:

- Automotive industry;

- Electrical and Electronics;

- Metalworking, mechanical engineering;

- Chemical industry;

- Medicine and pharmaceuticals;

- Food and agriculture;

- Education;

- Other areas.

Grips and tools for robot arm

Robotic manipulators are equipped with various end devices, from the most straightforward – pneumatic or electromagnetic. Moreover, they hold the part with a vacuum or magnetic field to complex robotic arms with an electromechanical or hydraulic drive. As well as all kinds of special tools – twisting, welding, cutting, etc.

Robot tools are divided according to different principles.

According to the principle of action:

- Mechanical;

- Magnetic;

- Vacuum;

- With elastic chambers deformed under the action of air or liquid injected inside.

Moreover, according to the nature of the base:

- Centering;

- Based;

- Relocating.

By the nature of fastening:

- Irremovable;

- Interchangeable;

- Quick-change;

- With automatic change.

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC