Take you to understand the functions and advantages of CNC milling machine

2022/08/13 By 兰兹

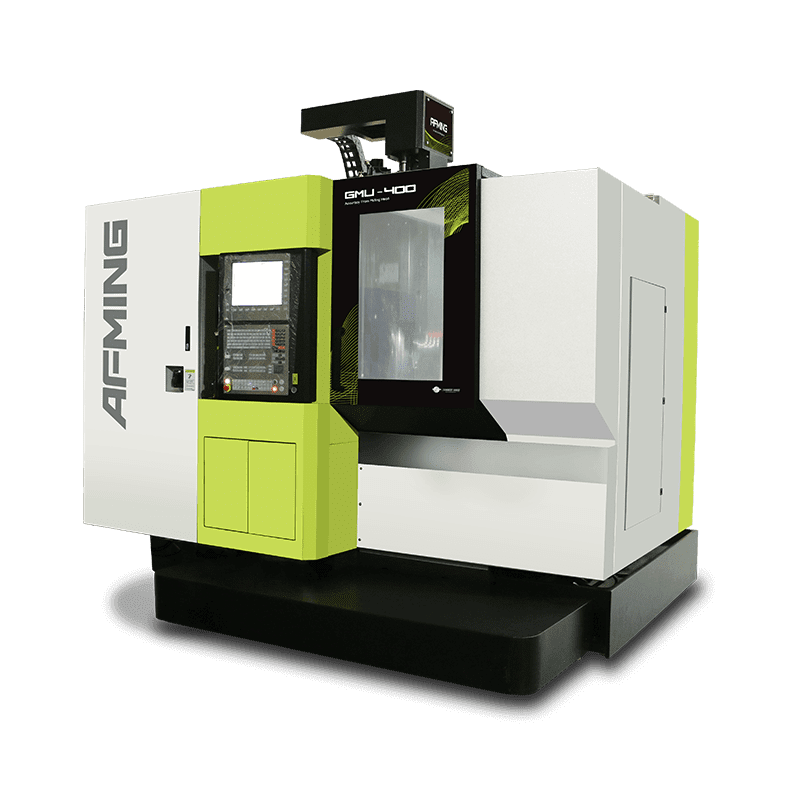

CNC Milling Machine is designed to make a highly-precise product using various materials and polymers. A milling machine’s primary purpose is to shape a workpiece into the required shape mechanically.

CNC Milling Machine produces High-quality objects with high precision and finishing. CNC denotes that the milling machine is under computer control. Using instructions from the CAD file, milling CNC machines use a rotary tool that cuts away the material to construct the part design. The computer regulates the cutter’s operation and coordinates, requiring little human involvement in manufacturing.

What is its Function?

A CNC Milling Machine reads coded instructions, executes these instructions, and begins the CNC milling. It creates a 3-D CAD file demonstrating the finished part is the first step. After completing the project, it will be converted to a readable format. Then, use CAM software to export these data to the CNC machine program. It accurately and effectively represents the CAD design of the selected materials.

The machine works with a rotatory cylindrical tool known as a Milling Cutter. The cutting angle and movement along the axes can vary depending on the milling machine utilized.

What are the Uses of a CNC Milling Machine?

A Milling CNC machine uses subtractive machining technology to produce complicated pieces for several industries. Through its 3, 4, or 5 axes, the milling machine shapes the workpiece to create a finished product. The finished object is more detailed and complex depending on how many axes the device uses. Many industries, including the automobile and medical sectors, employ CNC milling machines to create complicated parts.

Features of CNC Milling Machine

Typically, The milling machine has seven main components.

Knee

The knee is movable but fixed to the column. The worktable and saddle are supported by it. On the Z-axis, Satisfy lowering or lifting.

The primary support structure for the machine is the column. It serves to strengthen the other machine parts.

Saddle

The saddle can move with the spindle’s axis and is located above the knee and the workbench. If necessary, it shifts the workpiece horizontally.

The space secures the workpiece on top of the saddle, known as the worktable, depending on the model.

Spindle

An electric motor powers this rotating component, which holds either the machine tool or the arbor.

The cutting tools are mounted on the spindle, which functions on three linear axes since the most challenging materials can be precisely and quickly sliced through.

Arbour

Horizontal milling machines employ arbors. As a shaft, it can install various machine tools.

Ram

Usually found in vertical milling machines, the ram is fastened to the top of the collum, which supports the spindle.

Machine tool

The element that carries out the milling operation is the machine tool. It removes materials from the workpiece while being supported by the spindle. Machine tools come in a variety of types.

Advantages of CNC Milling Machine

Here are a few points to justify the advantages of a Milling CNC Machine.

Best Quality & High Precision

High levels of accuracy and precision are inherent to the CNC machining process, which leaves minimal opportunity for error. It uses a computerized program and inputs 3-D format designs created using CAD (Computer-Aided Design).

Without requiring any input from the user, the machine follows the instructions. These automated procedures make the highest precision possible, Ensuring that even the most complex and limited geometry is not a problem.

High Production Output

Due to the automated methods, CNC machines can function at a level that allows for significant production levels if there is a need for mass production while maintaining a high level of finishing and quality consistency. In that case, CNC milling is a reliable and well-liked alternative. Three-axis machine significantly lifts operation and programming, providing excellent accuracy at a reasonable price.

Requires Less Labor

The use of CNC milling machines significantly reduces the labor force. The machine’s tools can rotate at a maximum RPM (revolutions per minute) of thousands, producing a high production output while saving time.No manual process could provide a result like that. Notably, a more straightforward design requires less human involvement.

High Degree of Uniformity

CNC machining tools require the highest degree of accuracy. Because a computer program controls the movement, every component is manufactured with equivalent precision. Mass production of products and guarantee the quality of each finished product.

What is the price of a CNC Milling Machine?

The price Milling CNC Machine depends on several variables. The cost of CNC machine tools depends on the function and type. The material and part complexity are other variables that affect how much CNC milling costs. Click here to learn more about CNC Machining Services and Costs.

CNC Milling Machines Manufacturer Worthy of Trust

CNC milling has aided the Production and Manufacturing World to a vast extent. The Milling CNC Machine can create highly intricate and complex items. Topstar is a reputable enterprise for buying CNC Milling machines. Visit the Topstar Website to purchase tools and appliances for your business specifications.

Read more: Things you should know about Horizontal mixers.

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC