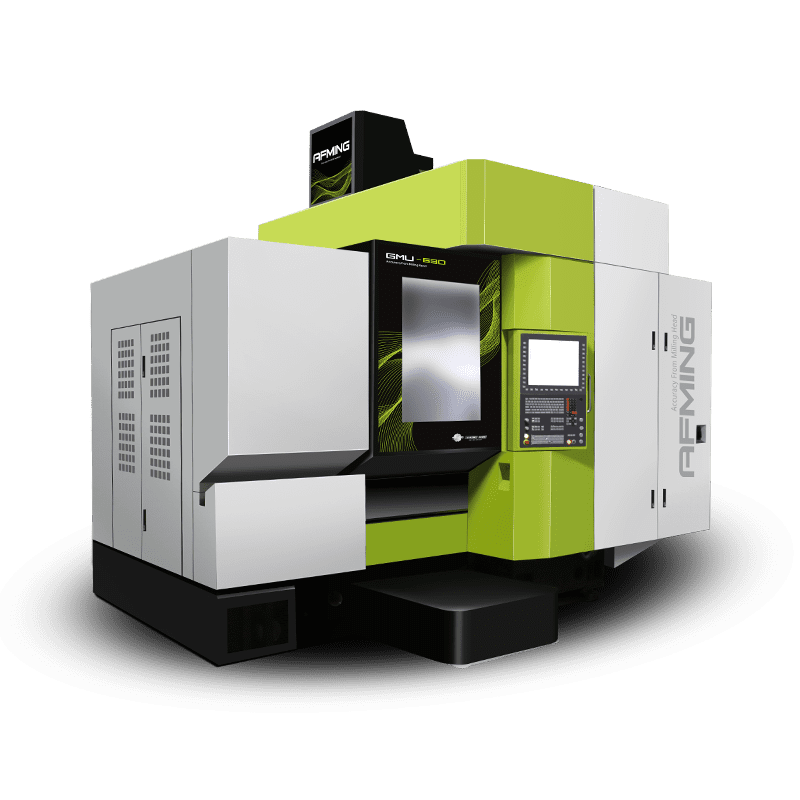

How a Horizontal Machine Center is the Best Option for Business?

2022/08/14 By 兰兹

Unlike vertical machines where the spindle is oriented vertically, Horizontal Machine Center is a tool that utilizes spindles that operate parallel to the ground. Horizontal CNC mills use short, more powerful cutting tools that may create more deep cuts on the workpiece due to their horizontal orientation.

Depending on the machine, Horizontal Machine Center can make several cuts and cut more quickly. When facing and pocketing, chips can also be taken off more quickly. For lengthy or significant production runs, horizontal milling machines are helpful due to their enhanced speed and precision.

Benefits of Horizontal Machine Center

Horizontal Machine Center offers accurate computer-controlled cuts and close geometric tolerances. CNC horizontal milling machines reduce the possibility of human error. Here are a few Benefits of a Horizontal CNC Machine Center.

High-Speed Results

There is a lot of overlap between horizontal and vertical CNC machining, even though they are better suited to different jobs. Here are some significant benefits of horizontal CNC milling for your project.

Strong Feed Rate

Rapid feed through the machining center of the substrate using horizontal CNC mills eliminates the need for deep milling passes in favor of lighter cuts, improving productivity and quality overall. It keeps the workpieces and cutting tools moving to maintain a fast feed rate.

Alternating Angles

Numerous angles can be used to apply tools to the workpiece using horizontal CNC equipment. Machines with four and five axes concurrently use many spindles at various angles, which enables them to produce complex pieces in fewer cycles.

Multi Cutting Axis

Horizontal CNC machining operations are quick due to more effective feeding and simultaneous multi-axis cutting. Operators and part designers can construct fluid command sequences that promote fast production with fewer part cycles.

Complex Parts Machining Capability

The instruction sets that CNC machines use are obtained from product design files. They are exact when making intricate cuts and can manipulate workpieces from various angles. Because of this, the machinery can produce anything, from standalone goods to parts for complex assemblies.

Tools for Advanced Platforms

The numerous tools that may be added to horizontal machining centers enable them to handle various materials and processes. Modern CNC machinery can be installed with new tool attachments and upgraded with software that can perform matching commands as they become available since cutting tool technology is continually changing.

Time-Saving

Horizontal Machine Centers are designed to create large quantities of goods with minimal downtime. Such processing adds significant time savings to the production process.

Expanded Capacity

A wide range of functions are available from Horizontal Machine Center, and operators can quickly change programming sequences to switch between different orders and products. Manufacturers and product designers have more incredible options and flexibility with practically any project using CNC machining centers.

Reliable and Accurate

Without deduction or the possibility of human error, horizontal CNC machines carry out precise instructions. Every product is a nearly exact fit to the original design within incredibly tight tolerances since every spindle produces accurate cuts and adjustments.

Simple Chip Evacuation

Horizontal CNC Machines wear out more quickly and produce products of worse quality when chips are left in them. Horizontal CNC mills with integrated tools minimize the possibility of chips remaining in the equipment and remove the requirement for operators to stop the machine from clearing up chips regularly.

The cleaning process is made simpler and quicker by limiting the dispersion of chips and extra workpiece material around the shop floor.

High-speed CNC horizontal machining centers are beneficial for quickly creating complex parts since they are intended for faster processing and chip evacuation.

How does Vertical Horizontal CNC Machine Centre Differ from Each Other?

Both horizontal and vertical CNC tools are capable of a wide range of intricate cutting and machining operations. Vertical setups are suitable for basic production requirements because they are affordable, almost universal, and straightforward. Creating essential parts and producing goods that require only one side to be machined are ideal applications.

Although more expensive and less frequent, horizontal CNC mills produce products with a smoother finish and work at a significantly faster production rate. They are perfect for cutting workpieces that include slots or holes, must be machined on several sides, or are constructed of heavy materials.

Advantages of Horizontal CNC Machine Milling

A horizontal milling machine’s cutting tool resembles a circular saw more than a vertical milling machine, which is more like a drill press. Numerous customization options, such as multiple cutters or rotating universal beds. They are available for horizontal milling centers, allowing users to cut horizontally at different angles. A horizontal mill is similar to numerous machines being used simultaneously.

Machines for horizontal milling have a long lifespan. Thanks to their size and robust construction, they can handle larger and heavier materials without the risk of causing the machine any harm.

Horizontal CNC Milling Machine can simultaneously mill, drill, ream, bore, ream, and tap. When processing items in one-time or small-batch production. Ensure modern machine tool and control concept, compact structure design, and high precision processing standard. The lathe also requires density measurement and process control.

Horizontal mills can handle higher volume production projects because they are designed more robustly. Each machine component is built to last longer under the particular stresses that apply to HMCs.

Compared to vertical mills, machines with this stiff design vibrate less, deflect less, and operate more smoothly. A single HMC may perform the functions of up to three different machining tools because of its mechanical construction.

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC