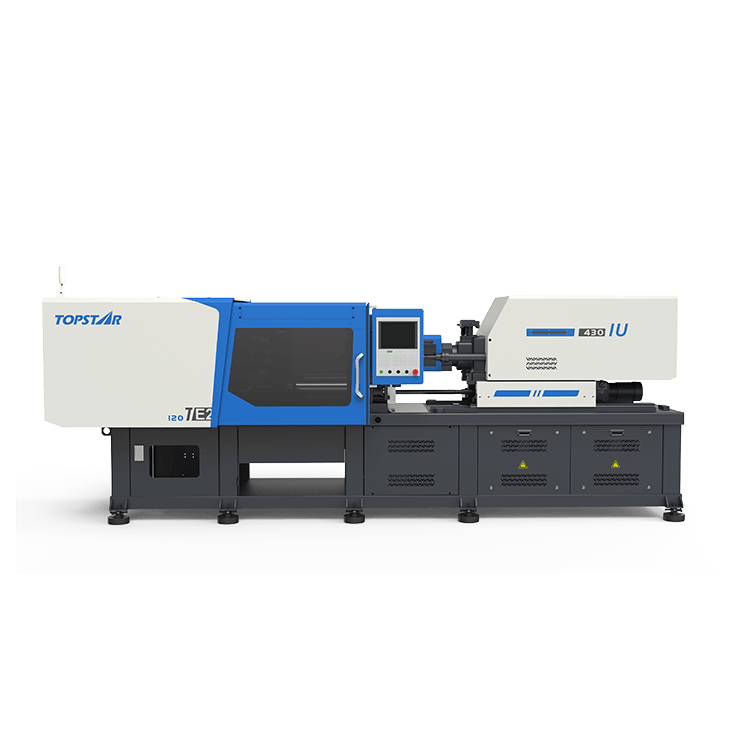

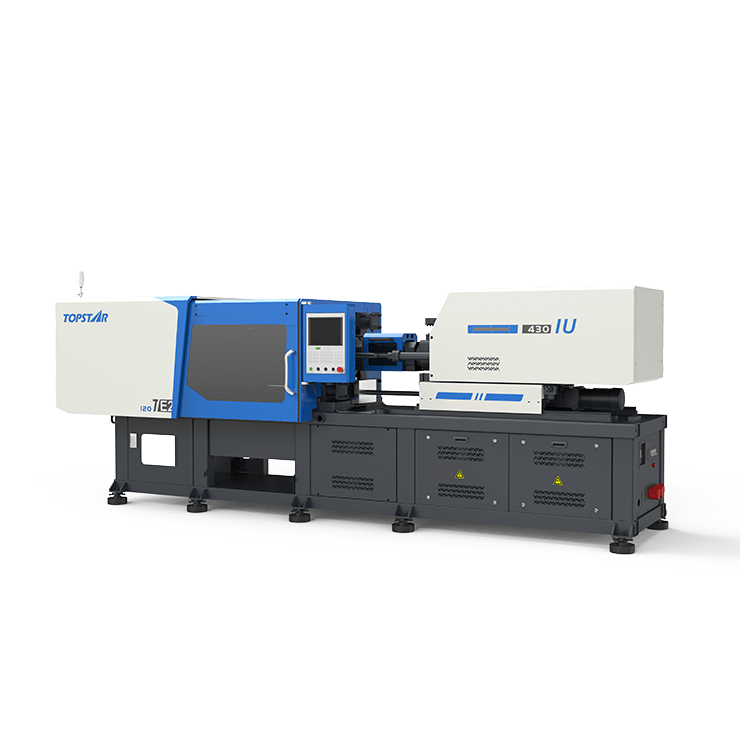

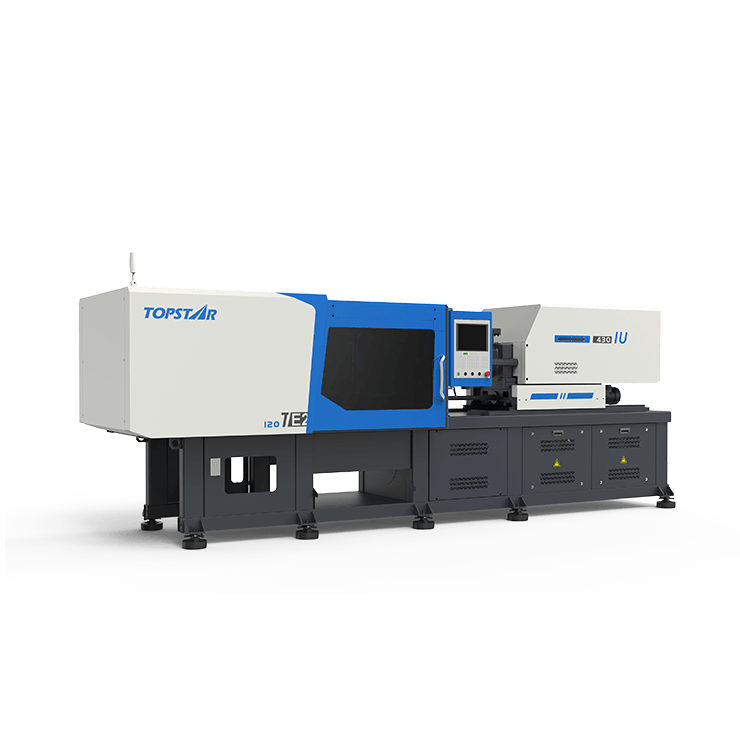

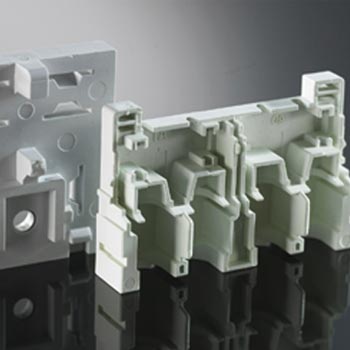

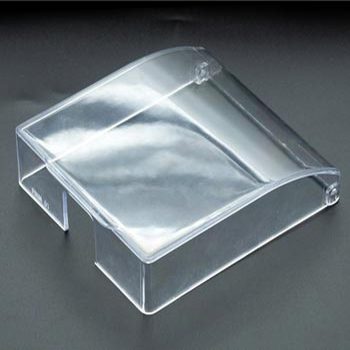

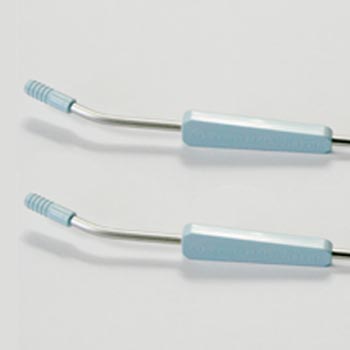

TEII Series All Electric Injection Molding Machine(90T-460T)

This series of all-electric injection molding machine is elaborately built by Japanese expert team and adopts the most advanced all-electric technology from Japan, including motion control, lubrication, servo drive and mechanical design. The whole process from design to production is monitored by Japanese experts to build world-class products.

Characteristics

- 1. Intelligent electric mold opening and closing: high repetition accuracy, stable clamping, precise opening position.

- 2. Smart electric injection motion control: accurate time, pressure and position of PV conversion.

- 3. Full digitalization bus platform: expand more optional functions.

- 4. System dynamic multi-stage control: time, position, pressure repeat precision monitoring.

- 5. Optional high injection speed: by changing the injection unit, satisfy the diverse needs of customers.

Application Industries

- Medical, Home Appliances, Containers, 3C Electronics, Toys, Cosmetics, Auto Parts, FMCG.

Adequate supply of goods, available for delivery within 35 days.