What is an excellent industrial robot supplier?

Choosing an industrial robot supplier is not simple. You need to consider many factors, including the size of the supplier and its sales team, component availability, training and re-training, and the robot purchase contract. We will examine these issues in detail below.

Single source supplier

A single source supplier provides all of the components for a robot installation. This means you have one company to contact when looking for a robot, and it doesn’t matter what additional equipment you need to run your robots. A single-source supplier will provide everything from safety guards to tooling fixtures, so you don’t have to worry about multiple vendors leaving your project incomplete.

An excellent industrial robot supplier will also have a well-trained sales team who can help with anything from design assistance to installation and maintenance after the sale. Choosing an industrial robot manufacturer with good customer service means that your team can call them at any time with questions or concerns they may have throughout their project lifecycle–not only in initial ordering but also during training sessions or troubleshooting issues. When it comes down to it, choosing an industrial robotics company should be based on its ability to deliver cost-effective products on time while providing post-sales support when necessary (and not just its price).

Supplier sales team

A good supplier’s sales team should be knowledgeable, experienced, and available to answer your questions. They should be able to provide a product demo so that you can see it in action before committing to purchase. Finally, they should be able to provide references from customers who have successfully used their product in similar situations as yours.

Component availability

An excellent industrial robot supplier will have a wide range of components available. This means that it will be able to provide a large number and variety of different kinds of parts, as well as spare parts and technical support.

You want to ensure that your industrial robot supplier offers comprehensive training for your staff to use the new equipment in their manufacturing process properly.

Supplier size

More prominent suppliers have more resources to help you. They can provide a better range of products and services, including in-house design and manufacturing, more excellent technical expertise, and an enhanced level of support.

Larger suppliers offer better pricing due to their economies of scale. Smaller suppliers may not be able to match the prices shown by larger companies. Still, they may be able to provide personalized services that are unavailable with more prominent operators.

Training and re-training

Training and re-training are critical to the success of any automated program. You will need to train and re-train your staff, management, suppliers, and customers for everyone to succeed.

The robot purchase contract

A robot purchase contract is a legal document that binds the buyer and seller of an industrial robot to their respective rights and responsibilities. The contract should include the following:

A description of what is being purchased, including how many robots are being sold, at what price, and if there are any special requirements for a delivery date or shipping method.

Payment terms for when payment will be made and how much it’s worth. For example, you might want to pay 50% upfront before shipping begins and the rest within 30 days after delivery.

An agreement about who owns which parts of the robot after it’s delivered—for example, does your company hold all software components but only own half of the hardware? Or does your company own all hardware but only one-third of the software? This will help define who has responsibility over maintenance costs down the road (e.g., when one piece breaks down). Also, if you’re using someone else’s software on top of theirs, make sure they have “commercial” licenses so they can sell it commercially without violating copyright law!

Choosing an industrial robot supplier is not simple

Selecting an industrial robot supplier is not simple. There are many factors to consider, including:

Benefits of buying from a single source: When you buy your robots from just one supplier, they can help you with everything from training your staff to ensuring that the parts and software updates are compatible. They can also offer better pricing when buying in bulk.

Benefits of purchasing from Topstar, a high-quality supplier: The larger the company is, the more likely it will obtain excellent customer service or help you develop future business growth plans. For example, if you want your team members to receive training on the effective use of their products, you may need a more well-known supplier with more employees who can quickly handle this task (without violating any rules).

And benefits of buying from a supplier that can train your staff: If there’s anything worse than spending money on something then realizing it doesn’t work for what you need it for—it’s having wasted time and energy trying new things out only after realizing later down the line that none were going anywhere near where required! This means knowing where best fit within space requirements while keeping an eye open towards future expansion possibilities, so we don’t find ourselves stuck somewhere unable–or unwilling–for change when necessary later down the line once the project gets underway.”

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

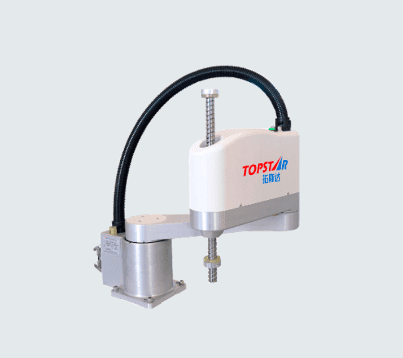

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC