CNC Machining Center- An Essential Investment for Your Business

2022/08/14 By 兰兹

Different machining centers can operate in various axes or planes. The y-axes, which move back and. The x-axes, which move left to the right, and the z-axes, which move up and down, are a few typical examples. The axis in which the machines are configured to work, such as horizontal or vertical, may be used to describe them. CNC machining centers can operate multiple axes. They employ various tools to carry out tasks, including drilling, boring, and tapping to construct the required part or mold. And machining centers can produce parts within this tolerance.

It can take a long time to program and set up the equipment. Once the equipment is configured, little operator input is typically required. These devices are widely utilized for mass-produced parts because of this. Programming and running CNC Machining Centers are both specialized trades. Depending on the country or location, Provide technical training in regional or local community trade schools. Online courses for programming machining CNC centers might also be accessible.

The use and application of CNC machining center

Manufacturing prismatic parts for the industry, such as gearboxes, partitions, frames, and covers, necessitates various machining processes, including milling, boring, drilling, tapping, etc. One machine may handle different machining needs by performing milling, lathing, and drilling operations.

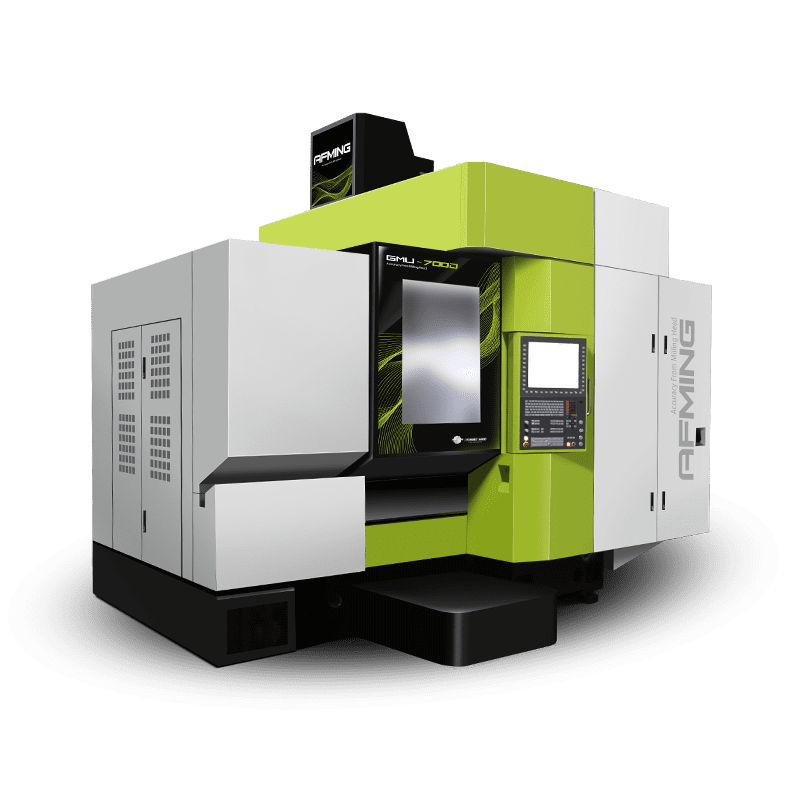

A computer numerical control (CNC) machining center creates parts or molds for the industry. The capabilities of these machines have increased along with technology, and there are currently numerous varieties of them. Technical training is available for those interested in operating or programming these pieces of machinery.

What is the difference between a milling machine?

A servo motor drives the machining center’s three XYZ shafts under a CNC controller’s control. Additionally, it incorporates an automatic tool changer that can increase the CNC machine’s machining effectiveness. The automatic tool-changing device is the primary distinction between a CNC mill and a machining center.

There are numerous varieties of milling equipment. They all perform the same milling, drilling, and tapping operations. Although manual milling machines are less expensive, their productivity and precision are low. CNC mill has excellent productivity, high accuracy, and high stability.

A vertical milling machine is open and manually controlled. The CNC controller completely encloses the machining center. The milling machine appears straightforward in comparison. While the CNC milling machine only has X, Y, and Z capabilities.

CNC machining center is a cutting-edge production tool

A CNC machining center is a cutting-edge production tool that can produce high-quality and high-precision parts. It is a computer-driven machine that uses various tools to cut, mill, and drill holes in different materials. This can be an essential investment for your business if you want to increase productivity and product quality in your manufacturing process.

Final

Why choose Topstar? Because Topstar has always loved setting the standard for reliable, high-quality CNC machining tools. Topstar’s priorities are growing your business, increasing profitability, and optimizing operations. The enterprise provides the first-class equipment needed to run the business and produce.

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC