Today, we can see the delta parallel robot in any highly automated manufacturing industry. Everyone wants to make their industries have the most efficient and performance capabilities through the development of science and technology. People used traditional machines to work more efficiently in sorting, packaging, loading, and unloading, but now, Delta parallel machines can improve all aspects. Let’s talk about this robot together today!

Delta Parallel Robots Offer Superior Accuracy and Flexibility!

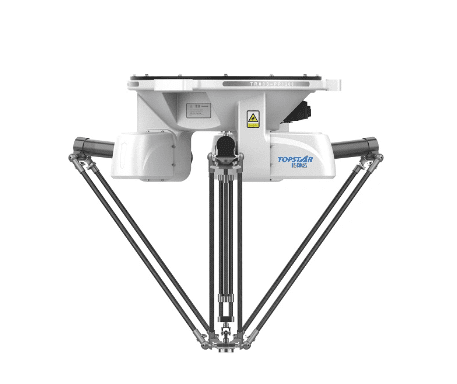

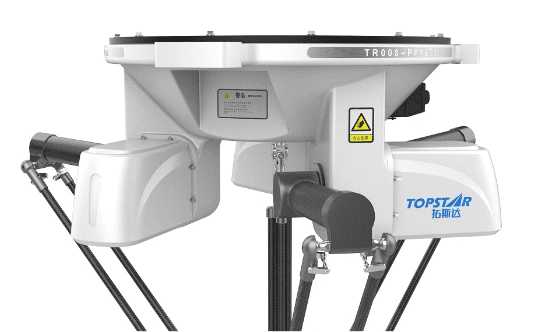

Delta parallel robots are known for their superior precision, speed, and flexibility, making them popular for various industrial automation and robotics applications. Their unique design enables them to operate at high speeds, making them ideal for applications requiring fast and precise motion, such as pick and place tasks. It is also known for its high precision and repeatability. Their parallel kinematic architecture helps minimize vibration or deflection during operation, increasing accuracy and reliability. Delta parallel robots are available in various configurations to suit different industrial applications, such as the number and length of arms, workspace size, and payload capacity. They are also easily reconfigurable, allowing rapid adaptation to changing production needs.

Delta parallel robots meet different needs of automated manufacturing!

They are highly versatile and efficient machines designed to meet the diverse needs of automated manufacturing. Delta parallel robots are easily integrated into existing manufacturing systems. They are seamlessly integrated into production to meet the needs of different industries and factories. In addition, our parallel robot also has a variety of customized services detailed to the diverse needs of each enterprise, even the height of the robot, the length of the arm, and so on. Based on the company profile we have learned, we will provide an in-depth automated Delta parallel robot that adapts to your company.

Delta parallel robot with high payload capacity!

Delta process linkage robots’ high-efficiency load capacity configuration suits multiple application fields. In manufacturing, these robots can handle heavy workpieces, such as welding, assembly, and painting in automotive manufacturing. In addition, they can also carry out high-load storage handling and handling tasks in logistics and transportation. Using a solid and flexible parallel structure, Delta robots can handle precision operations under high load conditions. Its design and control system configuration enables accurate position control and motion. This makes them excellent in applications requiring machining, assembly, or handling. The payload capacity of the Delta parallel robot is enhanced by reconfiguring the kinematic chain of the robot linkage. Adjusting the chain length symmetrically increases capacity for heavy loads without compromising performance.

Delta parallel robot has a lightweight design!

In today’s automation field, some friends choose the lightweight design of the Delta parallel robot because their application needs to be more compact and lightweight. One such example is the development of micro-delta parallel robots, which are relatively smaller than traditional delta-parallel robots and suitable for applications requiring high speed and high precision with limited workspace. We use lightweight materials such as aluminum or carbon fiber to construct the robot’s arms, linkages, and other structural elements to achieve a lightweight design. In addition, using compact, lightweight actuators and sensors also helps reduce the overall weight of the robot. The main advantage of this is the ability to achieve high-speed operation. Reconfiguring the kinematic chain of the robot’s linkages enhanced the payload capacity of the Delta parallel robot.

It is the ideal solution for high-efficiency industries!

We have used manual or traditional complex machines in the past ten years to complete these transmission tasks. The Delta Parallel Robots are an excellent choice for industries focusing on efficiency and productivity. Their speed, precision, versatility, and compact design make them valuable assets in a wide range of industrial applications, where their high efficiency increases productivity. Its fast, precise motion and high payload capacity enable industries to complete tasks faster, increasing production. Their size will not take up too much space for you, which reasonably solves the space problem. In the feedback of many customers, it is confirmed that this is the ideal choice for their production line!

The last point

When your enterprise does not use Delta parallel robots, you might as well try to use them. We have reason to tell you with confidence that this machine will satisfy you. If you feel the above sharing is not professional enough, you can contact our official website to communicate with our experienced staff. We are also delighted that such an article can bring you different inspiration and gains!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC