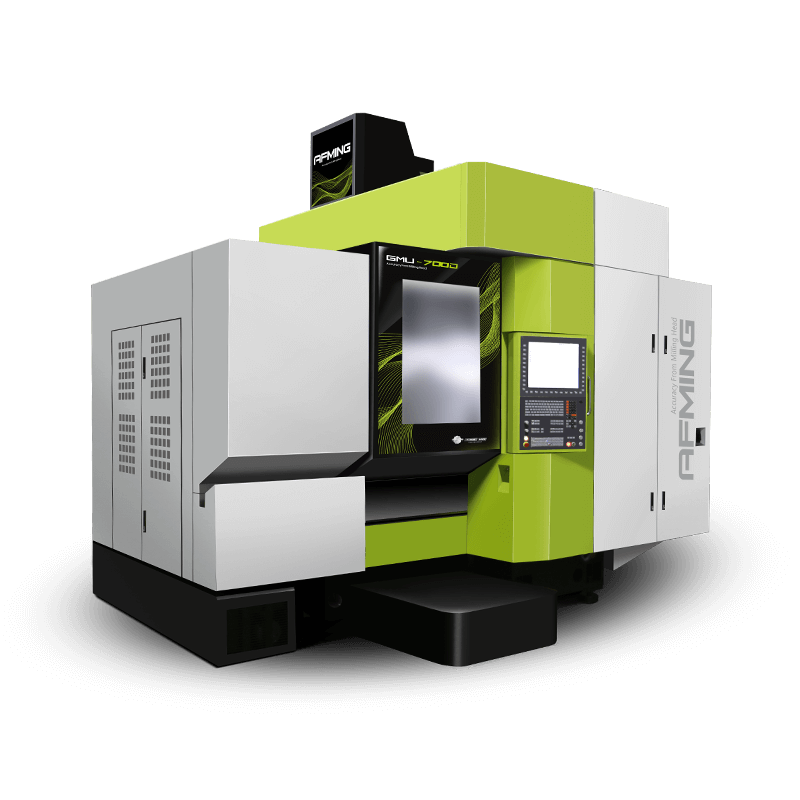

Five Axis Machine Center – Can Add Value to Overall Productivity

2023/04/04 By 兰兹

In today’s world, businesses and manufacturers must get innovative to stay ahead of their competition. The rise of the five-axis machine center is a perfect example of this trend. Manufacturing has evolved from using CNC machines with 2-axis capabilities and manual lathes. It produces very limitedly. Today, many companies are investing in 5-axis machines that can cut complex shapes and create advanced designs. This change has increased productivity exponentially by allowing manufacturers to develop more intricate products than ever—at lower costs!

What is a 5-axis machine center?

A five-axis machine center is a machining tool that allows you to make complex parts. It can be used in various industries, including aerospace, automotive, and medical. Five-axis machines can move in three dimensions and rotate in two; this allows them to perform operations like cutting, drilling, and milling on an object from all sides at once rather than just one side at a time–this means that you can create more precise shapes than with standard tools like mills or lathes.

Five-axis machines are becoming increasingly popular because they can quickly produce high-quality products while reducing material waste by up to 70%. They’re also safer because they don’t require operators’ hands near dangerous moving parts (like those found on traditional equipment).

How does a 5-axis machine center work?

The 5-axis machine center is a computer-controlled, multi-axis cutting tool that can be programmed to cut complex shapes. In addition to the standard x and y axes (front-to-back and side-to-side), it has an additional z-axis that allows it to move up and down. This will enable you to create parts with rounded edges or highly accurate features that would otherwise be impossible on other types of machinery.

In addition, because these machines have five axes instead of three, they allow you more flexibility when designing your product’s geometry. They can reach into areas where other devices cannot go without damaging them or becoming unstable.

What are the advantages of using a five-axis machine center?

A five-axis machine center can help reduce machining time and cost, increase accuracy and productivity, improve quality, and more.

The benefits of using a five-axis machine center are many. If you’re not sure whether it’s right for your company or project needs, here are some reasons why it might be worth looking into:

What is the difference between 3, 4, and 5-axis machine centers?

A 3-axis machine center is used for milling, drilling, and tapping. A 4-axis machine center can perform these operations along with turning. The 5th axis adds the capability of boring and reaming.

A 5-axis CNC machining center is often referred to as a “5-Axis” because it can rotate in all three planes (x, y, z) plus have an additional rotational movement around an axis perpendicular to those three axes called the “w” axis.

A Five Axis Machine Center can add value to your overall productivity.

A Five Axis Machine Center can add value to your overall productivity.

High productivity: It will reduce the overall time and cost of producing your parts and can improve quality.

Reduced costs: Using a five-axis machine center helps you save money because fewer parts are needed to make the same product, which means less material waste.

The future of five-axis machine centers

The future of five-axis machine centers is bright. The need for precision and speed in manufacturing will drive the use of these systems, which can add value to overall productivity.

This is not just a trend but also a necessity as we progress as a society and industry. If you want to learn more about how your company could benefit from using these machines, contact us today!

Five-axis machines are a good investment

5-axis machines are a good investment. They can be used to increase productivity, reduce waste and improve quality. In addition, they can help you reduce costs.

Here’s why:

Five-axis machines allow more efficient use of raw materials because they produce parts with less scrap material than traditional machining processes. This is because the engine uses five axes instead of three; therefore, it has more degrees of freedom available when cutting the piece. This means there is no need for excessive finishing after machining, and no additional milling operations must be performed!

Because five-axis CNC routers have so many different axes at their disposal (X Y Z A B), they have an increased ability to perform complex shapes without sacrificing surface finish or accuracy in comparison with traditional two-dimensional machines such as lathes or mills, which only move along one axis at a time (i).

To sum up

We hope this article has helped you understand the difference between three- and five-axis machine centers. As you can see, the benefits of five-axis machining are many, including higher accuracy and better surface finishes. You may also want to consider investing in one if you already have a three-axis machine but need more flexibility in your production process. If so, then we encourage you to contact us today so we can help you find a suitable device for your needs!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC