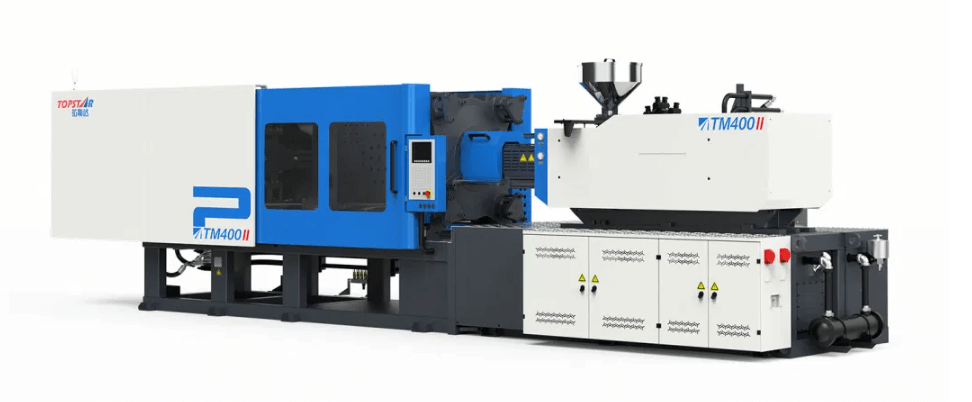

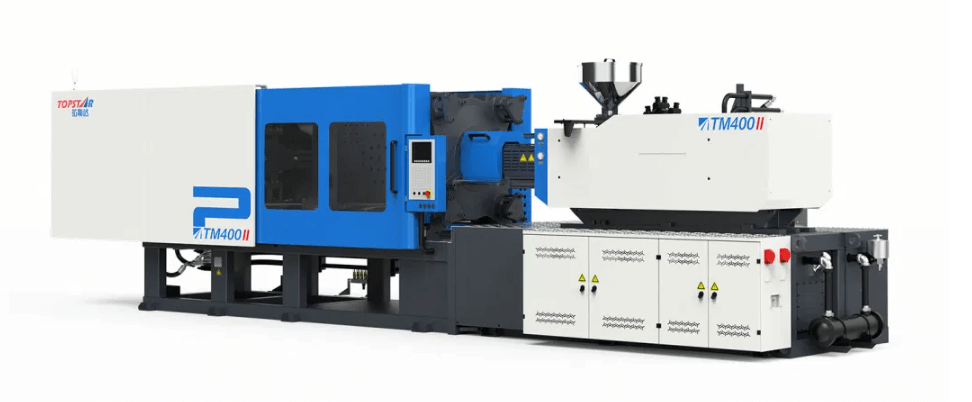

Plastic injection machines: key equipment that shapes modern industry

2023/09/11 By 兰兹

Modern industry is essential to any country’s industrial development, often incorporating high-tech equipment. Let’s take the plastic manufacturing industry as an example. Plastic injection machines are crucial equipment for shaping modern industry. They play a vital role in manufacturing, providing sustainability for products and enabling large-scale, efficient, and high-precision production of plastic products. Let’s talk about plastic injection machines through the following points!

Plastic injection machines enable mass production!

They enable mass production throughout modern plastic manufacturing processes, creating parts for other devices and even entire cars. They can quickly melt and inject plastic materials into molds, producing large quantities of plastic products of the same size and shape. This is very important for industries that require mass production, such as automobiles, home appliances, and electronic products. The high-efficiency production capacity of the injection molding machine brings higher production efficiency and lower costs, meeting the market’s demand for fast delivery and cost control.

Plastic injection machines make the processing of plastic products more precise!

Plastic injection machines are the most common and important type of plastic processing machinery. They are suitable for producing various products, from automotive parts to medical equipment. They use advanced control systems and precision molds to accurately control the temperature, pressure, and injection time of the injection molding process to ensure that the size and quality of plastic products meet the requirements. By using multi-cavity molds or multi-stage injection processes, injection molding machines can inject multiple identical or different plastic materials simultaneously to create products with complex structures and multi-layer compositions. Whether small parts or components with complex systems, injection molding machines can achieve high-precision processing and ensure product consistency and reliability.

They also offer flexibility and variety!

Plastic injection machines are very versatile and can be used to make products of different sizes and shapes by changing different molds, which is why they are so popular among manufacturers. This enables the injection molding machine to meet market demands while adapting to changes in product design and increases in personalized needs. In addition, they can achieve a certain degree of flexible adjustment and rapid changeover during the production process. You only need to set different injection parameters and mold configurations to easily change the product’s color, shape, size, and other requirements. Therefore, whether customized products or small batch production, injection molding machines can respond flexibly and provide high-quality plastic products.

They are also sustainable and environmentally friendly!

They are also sustainable and environmentally friendly, made using recycled materials, reducing the need for virgin materials. The recycling process also generates energy, so it’s a win-win! Plastic products produced by injection molding machines are also sustainable and environmentally friendly. Recycling and reusing plastic products extend their service life and reduce resource consumption. In addition, some injection molding machines can produce degradable plastic products. They can decompose plastic products into harmless substances through photodegradation, thermal degradation, or biodegradation, reducing pollution and environmental threats. They consume less energy than other equipment in the industry, making them more efficient overall. Since they’re designed to be easy to clean and maintain, you can spend less time maintaining your equipment and more time using them to create high-quality products!

Plastic injection machines are also constantly innovating!

They are constantly being improved. New materials and technologies are being used, as well as new designs and applications. This means exciting things are always happening during the plastic injection molding process! Their mold technology has also seen a lot of innovation and improvement. Modern injection molding machines can manufacture molds of various unique shapes and structures. Some rapid mold change technologies and software-assisted design tools have also appeared in injection molding machines’ manufacturing and application process, improving production efficiency and product quality. The innovation and application of plastic injection machine materials are also constantly advancing.

Final summary

People are pursuing high-speed and convenient products in the rapidly developing industrial field. The emergence of plastic injection molding machines not only enables high-speed output but also ensures quality. This is a must-have machine in every plastic manufacturing industry. If you also want your industry or enterprise to develop rapidly, go to our Topstar official website to purchase and place an order!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC

- 深圳人民欢迎你