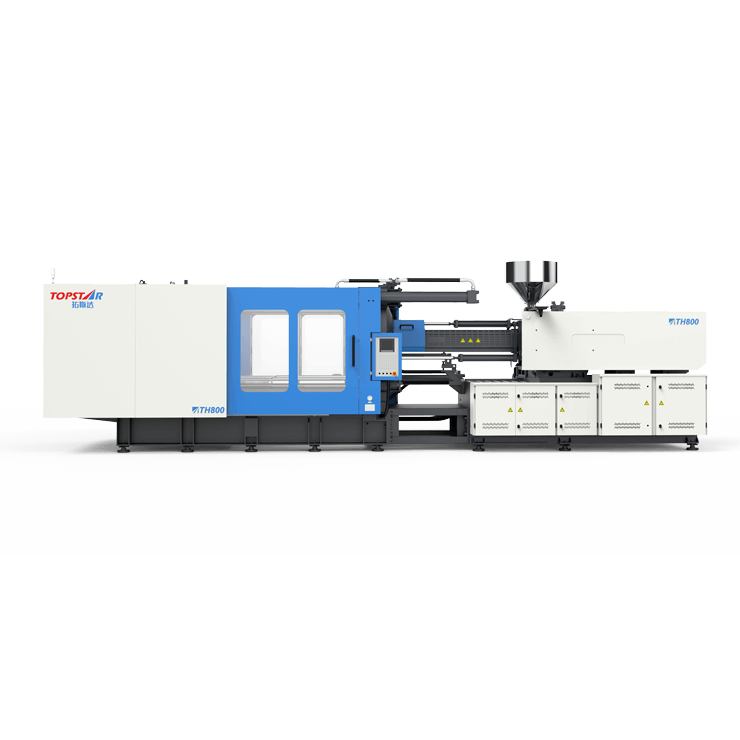

TH Series Direct Press Type Injection Molding Machine(130T-1400T)

Standard and civilian injection molding machines, two series. The clamping and injection platform are standardized.Two plate direct pressure center mold lock structure, provide the maximum mold opening stroke, meet the production needs of large specification, deep cavity products, meet the demand of automation parts pick-out applications.

Characteristics

- Small Direct Press Injection Molding Machine(130T-320T)

- 1. Central direct press clamping structure: Small platen deformation, parallel pressure on the mold, high molding accuracy.

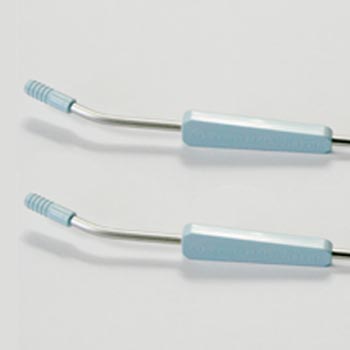

- 2. Double-cylinder for injection, linear guide for moving: Stable injection, sensitive action, high precision.

- 3. Patented sealing ring structure: High sealing reliability and long service life.

- 4. Full series of servo drives: CNC back pressure, KEBA controller.

- Medium and Large Direct Press Injection Molding Machine(550T-1400T)

- 1. Multi-cylinder direct press clamping structure: small platen deformation, parallel pressure on the mold, high molding accuracy.

- 2. Double-cylinder/Four cylinder for injection, linear guide for moving: stable injection, sensitive action, high precision.

- 3. Patented sealing ring structure: high sealing reliability and long service life.

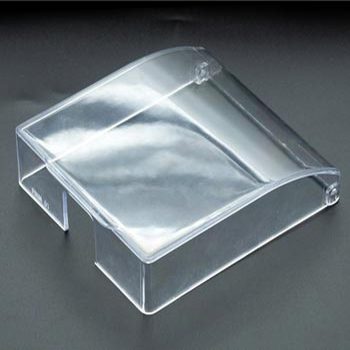

- 4. Large template spacing,high rigid template: suitable for deep cavity injection molding, product thickness is uniform.

Application Industries

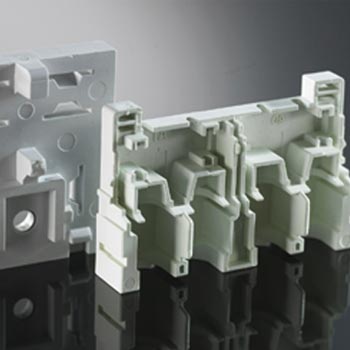

- 3C, Home Appliances, Photoelectric, Auto Parts, Daily Chemicals

Adequate supply of goods, available for delivery within 35 days.