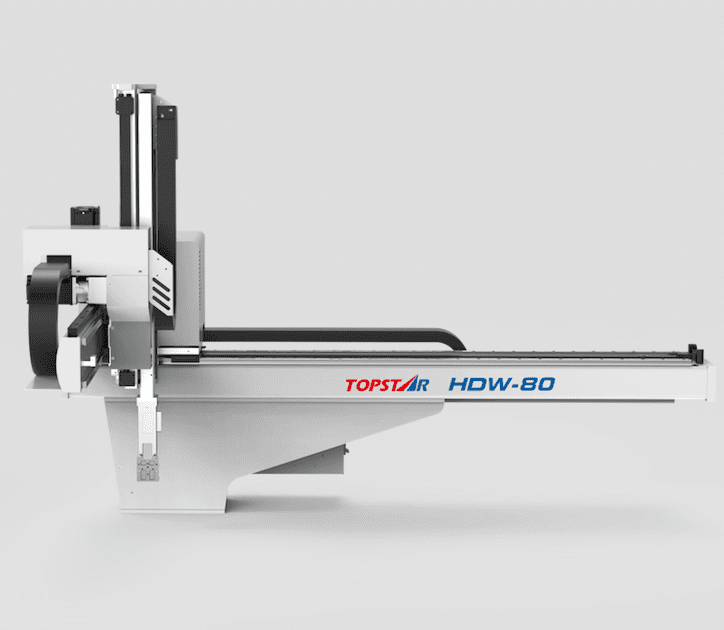

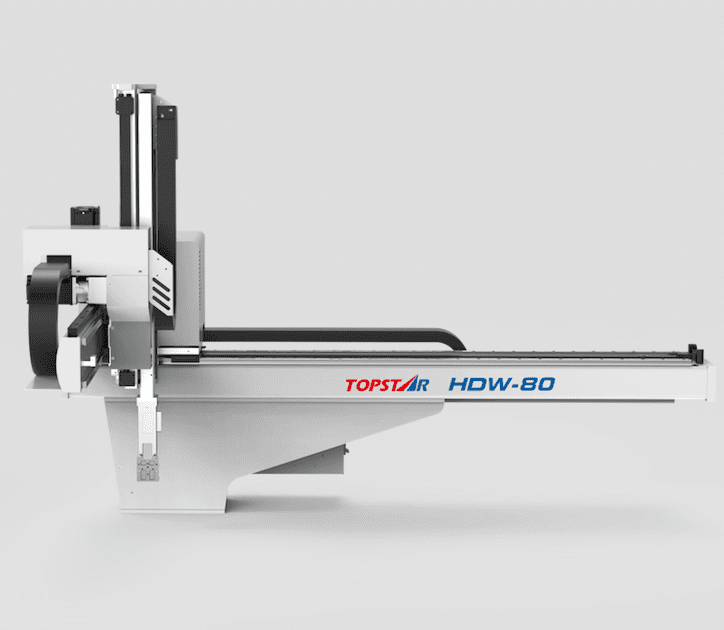

An injection robot arm is a highly automated process that uses computer numerical control machines to inject plastic, rubber, or resin into molds at high speeds. The robots can also be programmed for multiple injections. The cost of injection robots varies depending on the type and size of your business.

Purchase an injection robot arm for Faster Production

Injection robots are one of the fastest-growing segments of the robotics industry. Their ability to automate repetitive tasks can save companies time and money while increasing production quality.

Many companies find that they can use a robotic arm instead of manual labor for specific functions with great success. This is especially true regarding high-volume operations or those where the task is complex.

In addition to saving time and money on labor costs, these systems also reduce waste associated with human error–a significant concern for manufacturers producing large volumes of products daily. By eliminating mistakes made by people less skilled than machines at performing specific tasks efficiently, you’ll be able to produce better products faster than ever!

Injection molding – a highly automated process

Injection molding is a highly automated process that uses computer numerical control machines to inject plastic, rubber, or resin into molds at high speeds. Molds shape plastic, rubber, or resin into different shapes. The injected material then cools down and solidifies before removal from the mold.

Injection molding machines use two types of molds: metal or plastic (also called tooling). Metal molds are typically made from aluminum or steel and withstand higher pressures than plastic tools. Upwards of 20 tons per square inch (psi). Plastic injection tools are usually constructed from polycarbonate material. Still, they can also be made from nylon or other plastics, depending on the object you’re trying to create with your machine.

The robots can also be programmed for multiple injections.

The robots can also be programmed for multiple injections. And the robot arm will perform one injection, then move on to the next spot and perform another infusion. This allows you to complete many more parts in a single cycle than using manual methods, which is extremely helpful when working with large quantities of parts.

The robot arms can be programmed to perform multiple cycles within a single shift or over several modifications if necessary.

For faster Production and reduced waste, purchase an injection robot arm

Bing Buying injection robot arms can be produced faster and improve product quality.

Injection molding is a process that uses molds to create parts from a polymer or other material by injecting them into the mold cavity under high pressure. The process requires a lot of human labor and can result in large amounts of scrap materials if mistakes are made. Using an injection robot arm can avoid these issues because it reduces the need for human labor. Minimize waste/scrap and improve production speed and quality. Also allows you to produce different products.

In summary

The cost of injection robots varies depending on the type and size of your business. For example, a small company that makes products such as toothbrushes or pens will likely have a lower budget than one that makes cars or buses. However, no matter what kind of injection molding machine you purchase. In the long run, it will eliminate human errors while producing quickly, saving time and money!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC