Robots are becoming an increasingly common sight in factories, warehouses, and even homes. The first industrial robots were designed to do one specific task repeatedly. However, today’s machines can handle many tasks simultaneously and are becoming more flexible. That means you have many options when finding the best robot for your business needs.

When choosing an industrial robot

When choosing an industrial robot, there are three main things to keep in mind:

What kind of job will the robot do? This is a crucial consideration because it determines what type of robot you need and how much it will cost to purchase and install. For example, if you have an assembly line requiring precision parts to be assembled quickly with minimal human intervention, then a collaborative robot would be the right choice for your operation. On the other hand, if employees need assistance lifting heavy items or moving them around frequently throughout their workday (or both), an industrial arm might make more sense for your needs. The best way to determine which robotic solution is right for your business is by evaluating each case separately. Don’t forget about budget constraints!

How much space do we have available? Once again: this question should be answered before deciding which type(s) of robots are best suited for our operation(s). For example: If we’re looking at installing two different styles (like collaborative vs. industrial arms) but only have enough room outside where one could go…then maybe reconsidering what kind of automation would work best within those limitations.”

The first step is to determine what kind of job the robot will do.

The first step is to determine what kind of job the robot will do. The answer will help you decide which type of industrial robot fits your needs and how much force it needs to exert on its workpiece. Workpiece questions you should ask yourself:

What kind of material will it be working with? Does it need to pick up soft materials like cotton or fabric, or could it be exposed to high temperatures or corrosive chemicals? If so, look for an industrial robot that can withstand these conditions.

How much force does this material need to withstand before being damaged? If there’s too much pressure applied during handling by humans (or other parties), they may break down over time–and that could lead directly back into cost savings through reduced maintenance costs!

Next, you need to decide on the type of robot.

Now that you know what to look for in an industrial robot, it’s time to decide on the type of robot you need. Many different types of robots can be used for industrial applications, including:

Pick and place robots: These are used for handling materials and products in a manufacturing environment. They can pick up an object with one or more grippers and move it around until they find their designated location, where they will place it down gently without damaging anything else nearby (or dropping anything). This is ideal for automating assembly lines because these machines are perfect for moving parts around quickly and efficiently.

Handling robots: Handling robots typically feature two arms with pincers attached at the end so that they can grasp objects firmly before moving them around as needed–like picking up boxes from storage bins and carrying them over to another station where workers will unload their contents before putting everything back into place again after use!

Purchase and Installation

Finally, you want to examine how much it will cost to purchase and install your new find.

The cost of the robot itself is often just a tiny part of the total expense. You’ll also need to consider the following:

Installation costs (including installation by an expert or trainer)

Programming fees (if necessary)

Training costs (for those who will be working with this new piece of equipment)

Maintenance contracts or insurance plans that protect against damage due to wear and tear or accidents involving humans or other machinery on your site. These may be required by law in some jurisdictions.

Finding an industrial robot is similar to finding any machine.

When you’re looking for an industrial robot, there are three main things that you need to keep in mind. First, determine what kind of job the robot will do. If it is working on hard floors or carpeted areas, ensure the model you choose is compatible with both surfaces. The next step is choosing between different types of robots: those that require programming or those that come pre-programmed. Single-arm or multi-arm models; and whether or not they are safe enough for use by children (if applicable). Lastly, consider how much each option will cost. All these factors must fit within your budget!

Finally, let’s summarize.

If you’re looking for an industrial robot, many options exist. The first step is to figure out what kind of job you want it to do and then decide on the type of robot that fits that need. Once you have those two things figured out, it’s time to start shopping around!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

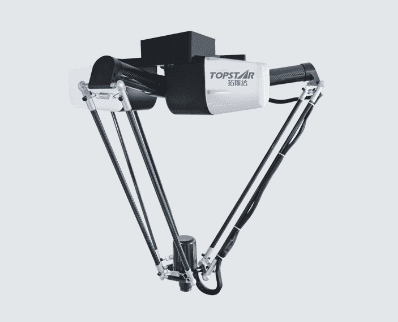

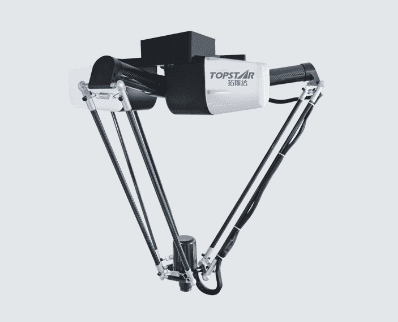

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC