Select the suitable injection molding machine for your enterprise

2022/11/26 By 兰兹

Select the suitable injection molding machine for your enterprise

An injection molding machine is a device that uses high pressure to inject plastic or metal into a mold cavity. The temperature inside the chamber will rise quickly, which helps to ensure that the plastic flows smoothly and evenly into the mold. After injection, the product should be cooled first to avoid thermal damage caused by hot air or water spray. The process occurs in an enclosed room with tight seals and no dust leakage during production.

What are the different types of injection molding machines?

There are two types of injection molding machines: horizontal injection molding machines and vertical injection molding machines. The former is more suitable for high-quality products. But the latter has a vast injection port, which can produce many small plastic products at the same time.

A suitable injection molding machine can improve your enterprise’s production efficiency and quality control. However, Before deciding which type is best for you, there are still some questions to answer.

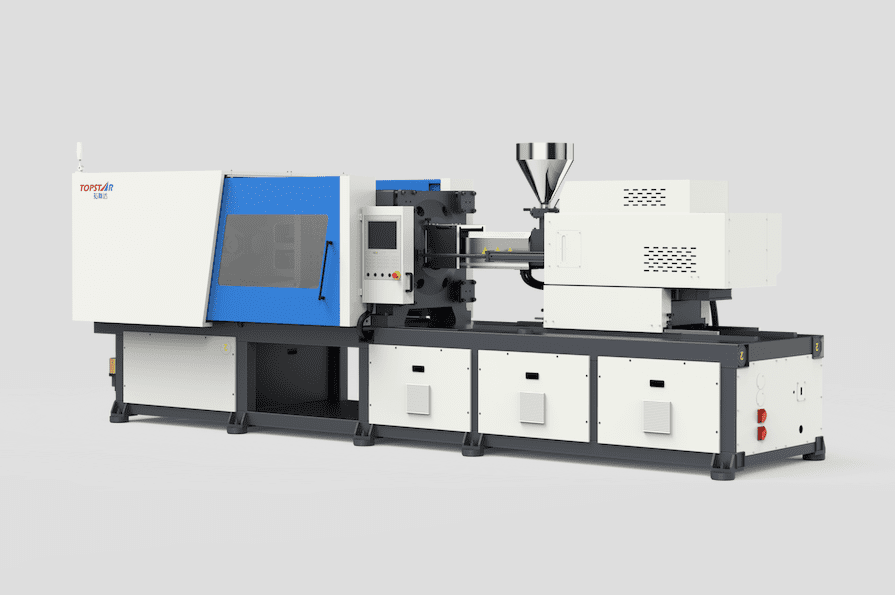

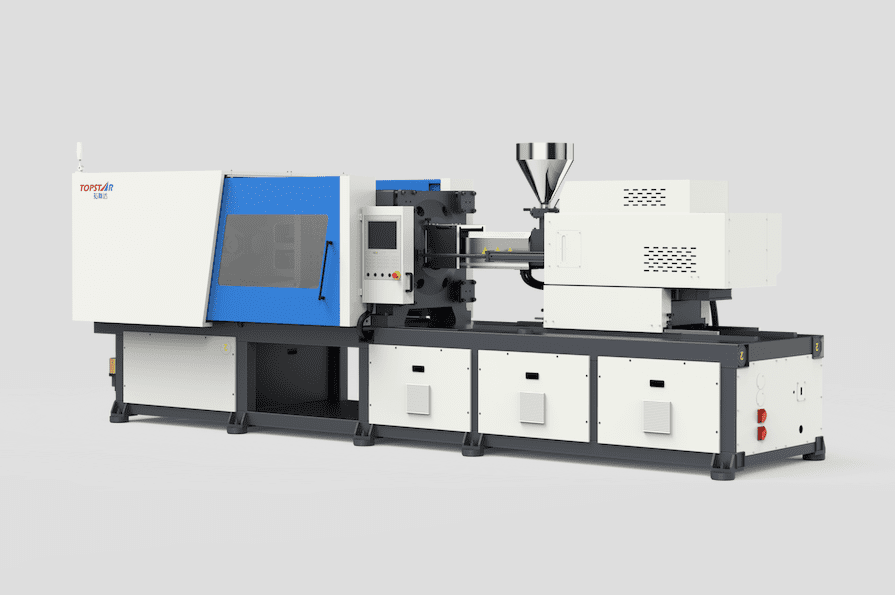

Horizontal, Injection Moulding Machine, Plastic Injection Moulding

If you are looking for a suitable injection molding machine, horizontal injection molding machines can be a good choice. The horizontal injection molding machine is ideal for high-quality plastic parts and large-scale production. Because it plugs directly into the power source, this mold-making equipment is energy-efficient and environmentally friendly.

Vertical, Injection Moulding Machine, Plastic Injection Moulding

vertical injection molding machines have a higher molding efficiency and can produce large quantities of products. If you are an enterprise with low requirements for plastic parts, vertical injection molding machines are more suitable for your needs.

How to Choose the Best Injection Molding Machine?

Injection Molding Machines are essential tools for any plastic manufacturing company. You must consider many factors while choosing an injection molding machine, such as material type, production capacity, productivity, etc.

Some Factors to Consider in Selecting Injection Molding Machines

It would help to consider the following factors to choose a suitable injection molding machine.

-The material of your products

-The volume and size of your products

-The complexity of your product design, if any

-Whether you would like to produce different types of products quickly.

The type of your production Whether you are a startup or an established company, The cost of an injection molding machine.

A suitable injection molding machine can improve your enterprise.

A suitable injection molding machine can improve your enterprise. The injection molding machine is a process that takes granules or powder and transforms them into a shape by injecting them under high temperature and pressure into a mold, where they are permanently shaped. Injection molding has been used for more than 100 years in the production of many everyday items, such as food cans, plastic bottles, toys, and many other products.

The main advantage of using an injection molding machine is that it can mass produce many different products at once with high precision at a relatively low cost per item compared to other methods like hand-made manufacturing or machining from solid blocks of material (which require much higher labor cost).

Finally, let’s summarize.

Topstar produces thousands of machines to meet every need in the industry. Choosing the right one for your business will depend on what you want to achieve with it and how much money you want to spend. You must research before buying a machine because it could cost more than expected if it doesn’t meet your needs.

If you need to know about these machines, please ask Topstar’s experts for help!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC