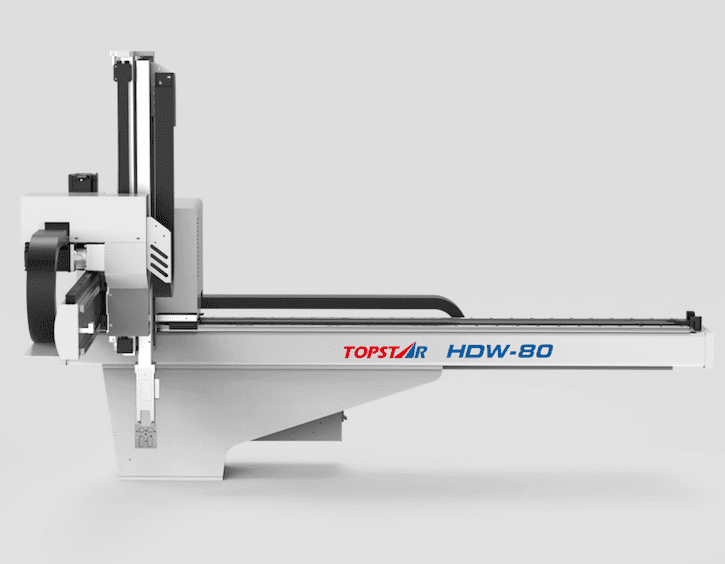

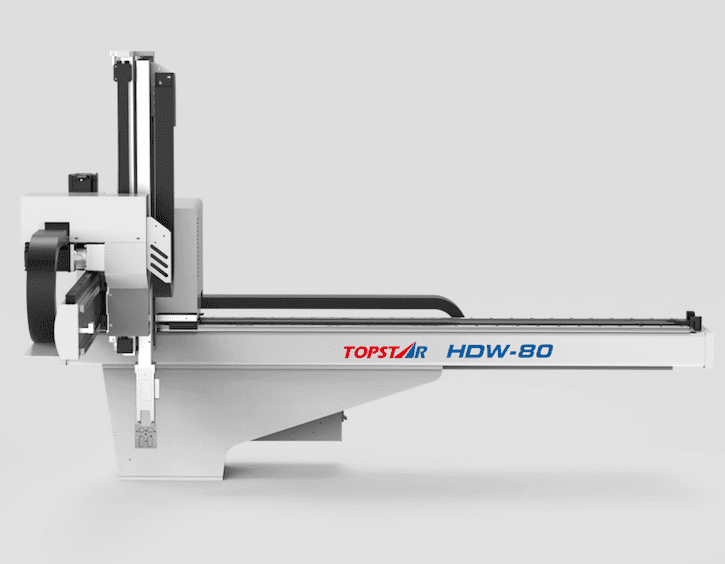

Servo Injection Robots Make Your Work Easier

If you manufacture products, you know how important it is to get your product out as fast as possible. You also understand that human error can slow down the process and cause problems for your production lines. That’s where servo injection robots come in: they can automate processes, so humans don’t have to deal with them. Here’s how these useful machines work and why they’re perfect for your operation:

With much of the automation on the production line, robots do the work

They are economical, efficient, and simultaneously on multiple lines. If you are purchasing a servo injection molding robot, keep the following in mind:

Make sure that there is enough space for them! You don’t want them behind other machines or tools; this will only slow down productivity.

Find out if there are any special requirements or regulations regarding noise or heat levels before purchasing any equipment like this (or any other kind). You may need unique ventilation systems and soundproof walls around each workstation where these machines will be placed.

You can implement the servo injection robot and let it inject the products into their final containers.

A servo injection robot is a great way to save time and money, especially when you’re working with multiple lines. A robot can be programmed to inject the correct amount of product into each container, so you don’t have to worry about making mistakes or wasting expensive materials. The machine can also handle many different products simultaneously, so if your company has multiple lines producing other things (like ice cream or shampoo), this might be the best option for them!

The Servo injection robot is more economical and efficient

Servo injection robots are an economical way to save time and money while making your production run smoothly. They increase the output of your company, which means more profits for you. They also allow you to do the job faster than human labor.

Servo injection molding robots are more efficient than humans, don’t make mistakes due to fatigue, don’t need breaks, and don’t need downtime – you get the idea! No complaints about their working condition – they will run until the operator tells them otherwise via the computer control panel or voice command system (if equipped).

Use on multiple lines simultaneously

Servo injection robots are also very easy to use. With a simple button push, your robot can perform tasks automatically. These robots are designed to work with multiple lines simultaneously, making them ideal for extensive manufacturing facilities that need to increase their output. Using these machines in various lines at once will increase your productivity further and get more done in less time!

Using a servo injection robot will let you get more done faster.

You can use a servo injection robot to perform a variety of tasks. The robot’s versatility makes it ideal for many industries and applications, whether you need to move parts around or assemble them. These machines are cost-effective, so they’re an economical way to save time and money while making your production run smoothly.

Servo robots are also easy to program and operate, so you won’t need highly skilled workers for the machines’ functions to succeed. Automating processes like these will allow employees who don’t have technical knowledge about robotics or coding to take advantage of their benefits as well!

Final

If you want to improve your production process, servo injection robots are great. It’s easy to automate these processes so that they run smoothly and efficiently while freeing up more time for other tasks.

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC