Smart Injection Molding Machine: Future Industrial Development

2023/09/06 By 兰兹

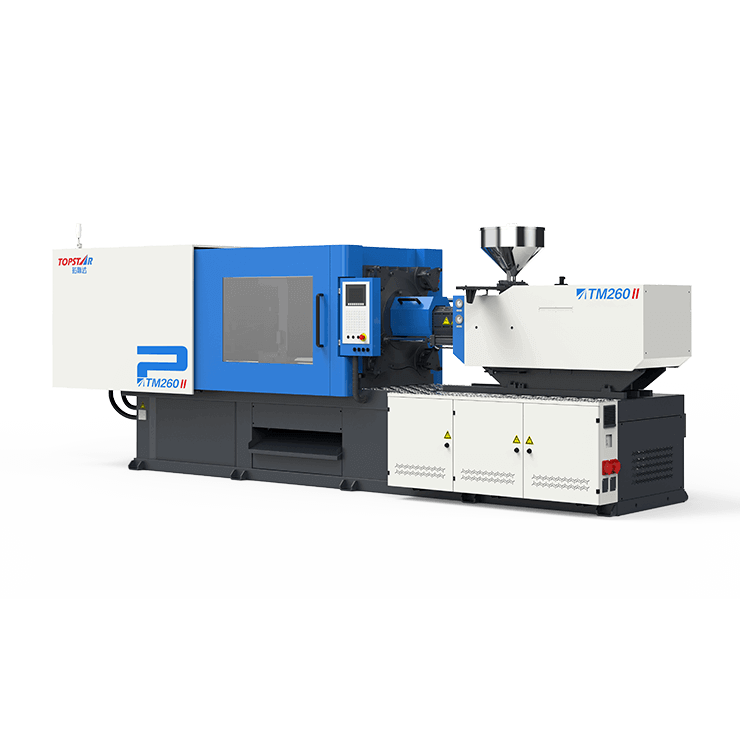

With the continuous innovation of science and technology, everything around us is becoming increasingly intelligent. In the injection molding manufacturing industry, traditional injection molding machines may not be able to meet people’s needs, so intelligent injection molding machines have emerged, becoming increasingly prevalent worldwide. Intelligent injection molding machine will be one of the future industrial development trends. And we, Topstar, have also developed this product. Let’s take this opportunity to talk about them together.

It is developed based on traditional injection molding machines!

Injection molding machines have been used for years and are widely applied in automobiles, household electrical appliances, and other industries. Intelligent injection molding machines are a new machine that combines traditional mechanical structures with intelligent control systems. Compared with traditional ones, bright injection molds can automatically monitor the process status and adjust themselves to meet different requirements by adjusting parameters such as temperature and pressure automatically without human intervention; moreover, they can also monitor their performance during production, which will significantly improve the quality of products produced by this machine.

The function and application of the intelligent injection molding machine

Intelligent injection molding machines adopt advanced energy-saving technologies, such as variable frequency drive systems, recycling systems, etc., which can reduce energy consumption and waste of resources. The environmental impact can be reduced by optimizing the injection molding process and reducing unnecessary energy consumption. By collecting and analyzing production data, they can understand critical indicators in the production process and make optimal adjustments based on the data. This helps increase productivity, prevent failures, and optimize product quality. It is more reliable than ordinary machines regarding safety and ease of use. These features make it ideal for large-scale production lines involving large numbers of similar products or complex-shaped parts that require high precision.

A new generation of intelligent injection molding machines reduces costs and increases efficiency!

In the past, the injection molding machine had a simple structure and lacked intelligent functions. They perform production tasks according to preset procedures. However, with the development of new technologies and materials, more complex requirements are put forward for injection molding machines.

Intelligent injection molding machines have many features that improve efficiency and reduce costs. Compared with traditional injection molding machines, energy consumption is reduced by up to 50%. Compared with conventional models, material consumption is reduced by more than 20%. Increase the flexibility of production planning by allowing users to customize products according to customer needs efficiently. Improve product quality by improving consistency at all stages of production.

The future development trend of their manufacturing industry

The future development trend of the intelligent injection molding machine manufacturing industry is as follows:

With the rapid development of science and technology, the materials used in intelligent injection molding machines will continue to improve and develop, which can significantly improve the performance and quality of products. For example, new high-strength aluminum alloy materials have been introduced, enabling manufacturers to produce high-quality products cheaply.

Integrating traditional mechanical design methods with software tools, you can quickly create unique designs by combining existing components or creating original parts from scratch. This allows you to create highly complex parts while minimizing tooling costs!

The combination of an injection molding machine and intelligent control system!

Intelligent injection molding machine combines an injection molding machine and an intelligent control system. The innovative control system is the heart of the equipment and is responsible for its operation. The smart control system obtains various data during the injection molding, such as temperature, pressure, flow, etc., through sensors and data acquisition equipment. Then, these data are processed through data analysis algorithms to obtain key indicators in the production process. Combining the two makes the injection molding process more intelligent and automated, improving production efficiency and product quality.

Future

More and more intelligent injection molding machines will be developed, so the design of injection molding machines in the entire injection molding field will be more extensive, and intelligence will become more common in industrial development. Topstar will be committed to providing you with the best solution on the front line and become your reliable partner!

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC