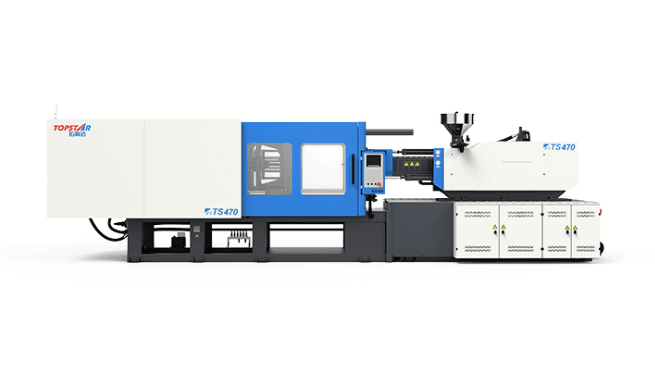

The Role of Toggle Hydraulic injection Molding Machines in the Plastic injection molding Industry

2023/08/28 By 兰兹

Toggle hydraulic injection molding machines are used for fast production and high-quality molds in the plastic injection molding industry. These machines are popular in the plastic injection molding industry. A toggle hydraulic injection molding machine is more durable than a traditional machine because of its toggle mechanism and hydraulics. A toggle hydraulic injection molding machine costs more than other devices, but it lasts longer and produces better molds. We have summarized some of its characteristics and will share them in the article.

Pushing hydraulic injection molding machine for rapid production and high-quality molding

The toggle hydraulic injection molding machine is used for rapid production and high-quality molding. They provide durable and long-lasting molds, which makes them expensive.

They are mainly used for mass production of high-quality plastic products. The structure of this machine is cumbersome, so it is not easy to install or disassemble it by oneself.

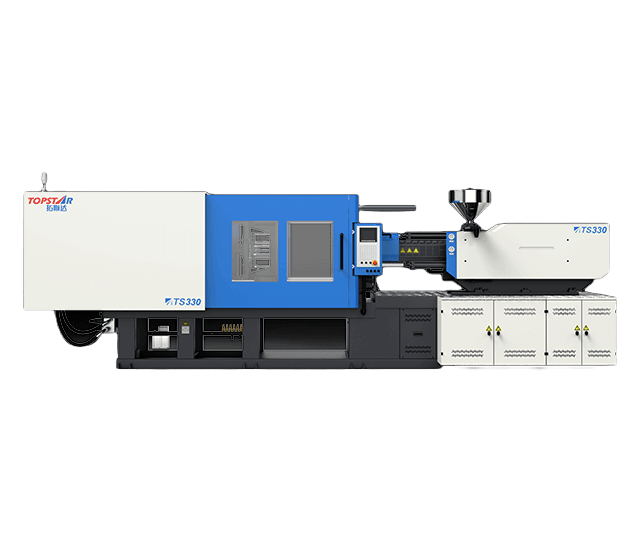

More durable than traditional machines

The elbow hydraulic injection molding machine is more durable than traditional machines. The reason is that it uses a toggle mechanism, which helps reduce machine wear and tear. So, the elbow joint hydraulic injection molding machine will have a long service life. The durability of this machine is one of its best features, making it very popular among plastic injection molding companies.

Another reason why elbow hydraulic injection molding machines are more durable than traditional injection molding machines is because they use electric motors instead of hydraulic power to drive the plunger and shuttle machine. Over time, wear on parts and bearings will decrease.

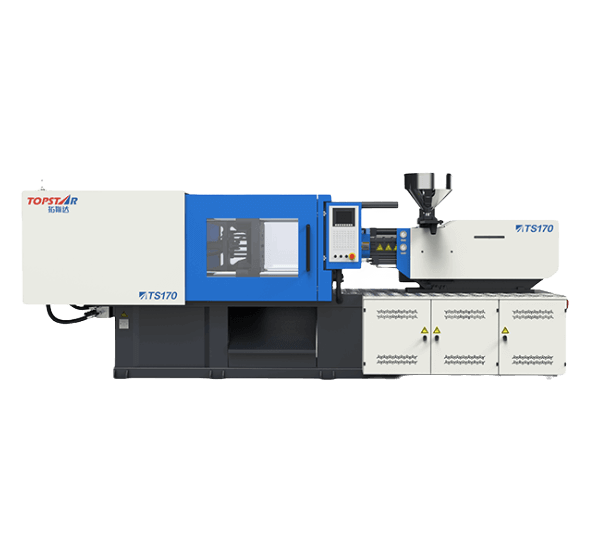

Famous in the plastic injection molding industry

The toggle hydraulic injection molding machine is popular in the plastic injection molding industry. The toggle hydraulic injection molding machine can be used in the automotive, electronics, medical, and food and beverage industries.

The reason why elbow hydraulic injection molding machines are popular is because they have many advantages. One is the ability to produce high-quality parts at high speed with the minimum operator involvement required.

Highly popular among enterprises in the industry

Due to its fast production speed and high mold quality, the toggle hydraulic injection molding machine is trendy among various enterprises in the plastic injection molding industry.

These machines have a long service life and are more durable than traditional machines. Their production capacity is very high, so you can produce many parts simultaneously on one device. They also have a high-quality mold that allows you to create better products with fewer defects than other types of molds.

There are also drawbacks – the cost is higher

We have introduced so many advantages of hydraulic injection molding machines for elbow joints, and of course, we should also mention its disadvantages. That is, its cost is higher than other types of devices. It has a high degree of automation, so that you can hire fewer people. This will reduce labor costs, productivity, and downtime caused by repair or maintenance issues.

Summarize the toggle hydraulic injection molding machine

The elbow joint hydraulic injection molding machine is a popular choice for plastic injection molding due to its fast production speed and high mold quality. These machines have a long service life, so they do not require regular maintenance. These machines have higher costs than other devices but will save you money in the long run because you don’t have to replace them frequently. Alright, that’s all for today’s content. If you have any further questions about the injection molding machine, you can contact us anytime through email or online communication on the website for consultation.

TRENDING POSTS

HOT TOPIC

- Air Chillers

- AP-RubberPlas

- Automation changed engineering

- automation of injection molding robots

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- elbow hydraulic injection molding machines

- Feeding And Conveying System

- Five Axis Machine Center

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- Industrial robot

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- Injection molding machine

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine procurement

- injection molding machine with a robot

- Injection molding machines

- injection molding plant

- Injection molding robot automation

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- molding material Dehumidifying System

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- plastic forming equipment

- plastic injection machine

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- plastic molding press

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- swing arm robot

- toggle clamp injection molding machine

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- x carve CNC