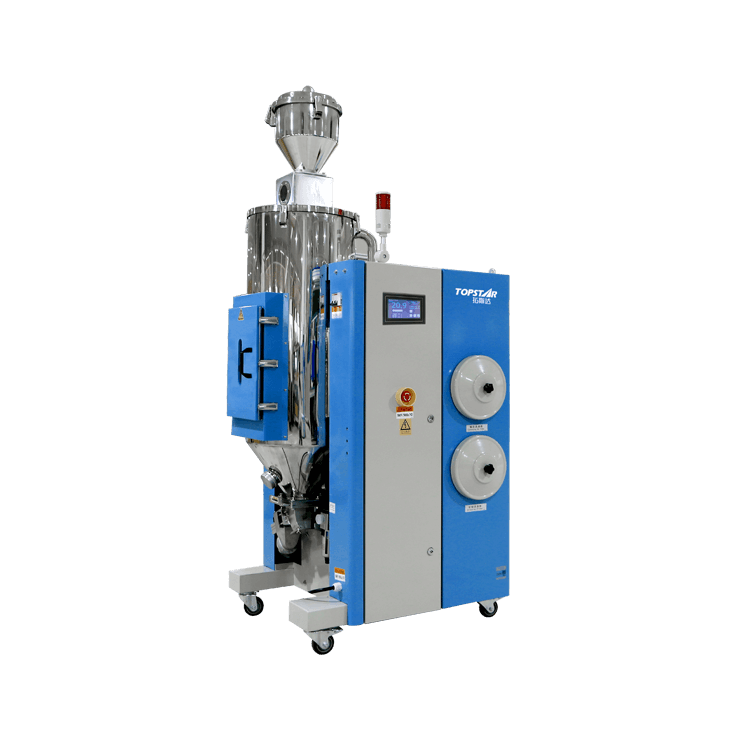

Drying and Dehumidifying System

Hopper Dryers are mainly applied to plastic material drying. Hot air is used to dry all wet materials which gain an even hot air flow to improve drying efficiency for assuring the quality of products.

Features

- 1. 3 in 1 compact dehumidifying dryers are equipped with honeycomb rotor which can acquire stable low dew-point drying air.

- 2. To integrate the function of dehumidifying , drying and two-stage conveying into single unit. Three-stage conveying function is optional.

- 3. Double-wall insulated hopper dryers features down-blowing pipe design to avoid heat dispersion for improving drying efficiency.

- 4. Feeding system is equipped with shut-off valve to ensure noremaining material in hopper tube.

- 5. Multiple safety protection device. Contact us

- 6. Optical-class models use mirror polished treatment on the material contact surface to avoid material contamination and collocate feeding system with closed-loop in order to avoid the possibility of moisture regain for absorbingoutside air during material conveying.

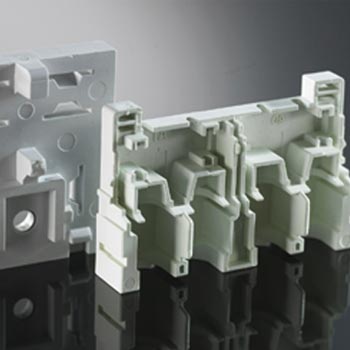

Application Industries

- 1. Electronics

- 2. Containers

- 3. 3C home appliances

- 4. Cosmetics

- 5. Auto parts

- 6. FMCG

Adequate supply of goods, available for delivery within 35 days.