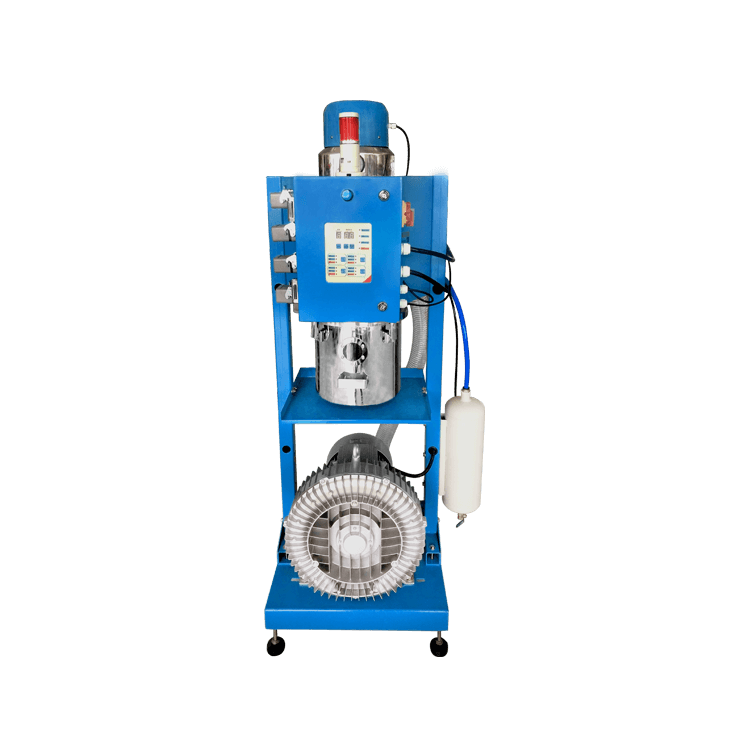

Feeding and Conveying System

Stainless steel (corrosion free) single hopper loader is designed to provide rapid transportation of free-flowing for virgin resin or regrind resin directly to the injection molding machine. The design of the hinged upper cover of the vacuum motor ensures quick cleanup time and easy maintenance.

Features

- 1. The main controllers and material hopper receivers are designed separately.

- 2. Can match 2 or above 2 hopper receivers to achieve one to multi combination conveying.

- 3. Material conveying capacities can be up to 700kgs/hr.

- 4. The maximum loading distance can be 10m, suitable for conveying materials over long distance.

Application Industries

- 1. Electronics

- 2. Containers

- 3. 3C home appliances

- 4. Cosmetics

- 5. Auto parts

- 6. FMCG

Adequate supply of goods, available for delivery within 35 days.