Good Product

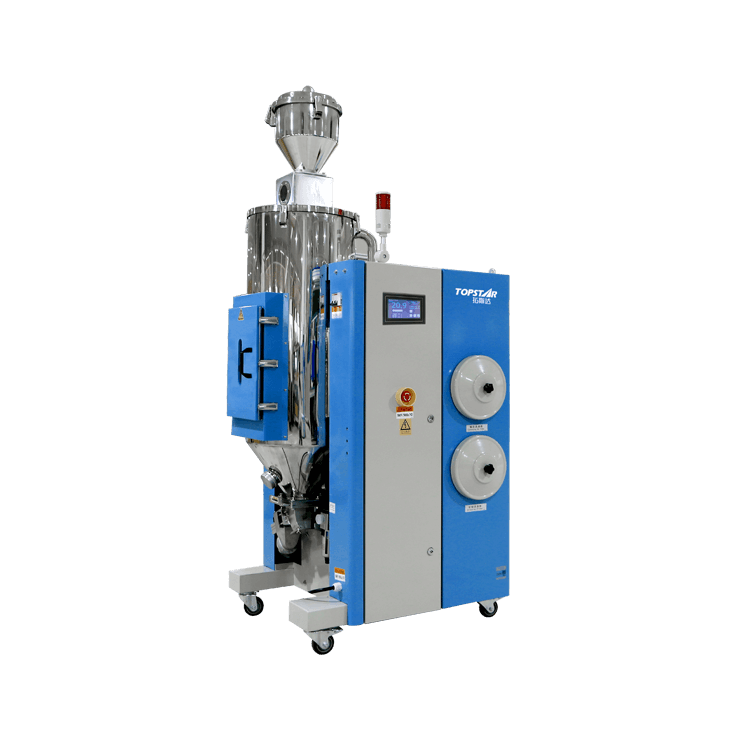

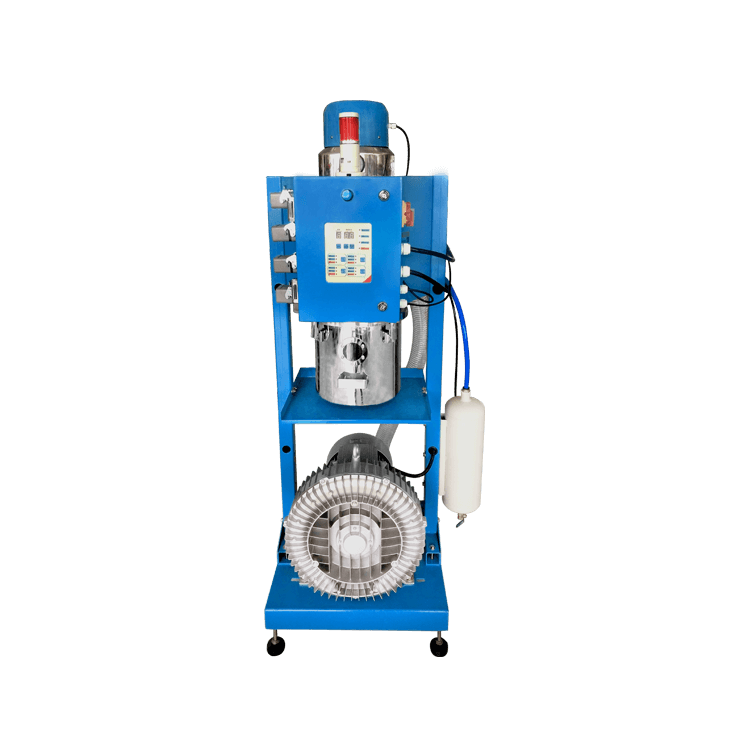

Auxiliary Equipment

Topstar's auxiliary equipment has a complete range: dehumidification and drying, automatic feeding, mold temperature control, automatic cooling, mixing and dosing, and crushing recovery system.

Products

Auxiliary Equipment

Products

Auxiliary Equipment

- High Performance

- Reliability

- Durability

- Universally Applicable

Did you know?

High-Security Equipment

Topstar’s direct press injection molding machine directly generates high pressure from the clamping cylinder on the plate, and the force point is in the same direction as the pressure in the cavity to achieve central clamping.

The plate deformation is quite small, and the product is not easy to flash. The force of the mold is balanced, and the service life of the machine is greatly extended.

For equipment of the same tonnage, about 10% of electricity can be saved after using the center clamping.

The plate deformation is quite small, and the product is not easy to flash. The force of the mold is balanced, and the service life of the machine is greatly extended.

For equipment of the same tonnage, about 10% of electricity can be saved after using the center clamping.

Training for Installation and Operation Correctly

Topstar services

To handle potential problems and ensure optimal operation, we offer the training resources you need to install and operate your packaging machine.

- Instruction-Statement of installation steps and operation cautions

- Video-Presentation of the installation and commissioning

- On-site Training-With an additional service fee

Technical Support

Whether your operation is located in Europe, North America, or the Middle East, our experts are standby to provide technical support services by video call or on-site assistance. Services include:

- The first installation and commissioning of the equipment

- Daily debugging and maintenance

- Emergency breakdown assistance

- Equipment optimization services

The Machinery Industry Professionals

- Customized Requirements

- Automation Solution

- Professional Packaging

- Delivery & Installation

- 24H Technical Support

The Topstar team delivered the Water & Electric Engineering project efficiently and perfectly in a complex environment with an urgent delivery schedule.

LUXSHAREICE

From EEA series to TE series, we see the continuous pioneering and innovative spirit of Topstar in the field of injection molding machines.

Dme Udaykumar

The robotic arms were installed and ran smoothly, which greatly improved our production efficiency!

Thai A-Tech

Listen To The True Voice Of Customers

We sincerely appreciate that more than 15,000 customers have witnessed the TOPSTAR growth and long-term supports.